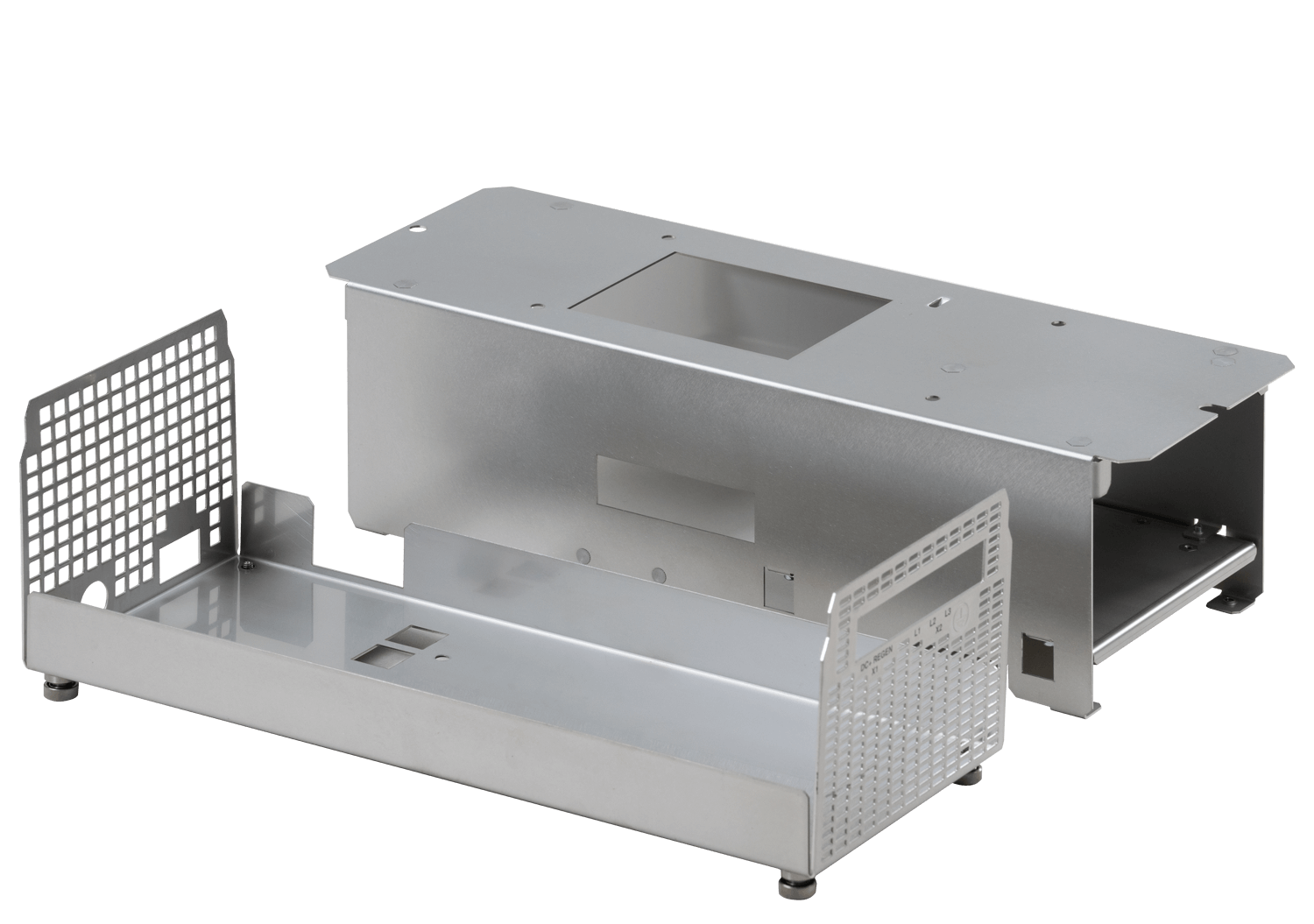

Custom sheet metal fabrication of assemblies, whether you need just 1 piece or 10,000 pieces, we can accommodate your order. Rapid quote and order turnaround with support all the way for your custom sheet metal fabrication project.

Based in Taiwan and serving clients around the globe, TAIWA delivers quick-turnaround online sheet metal fabrication solutions tailored to your 3D CAD files or engineering drawings.

Our team handles everything from precision prototypes to large-scale production, working with a wide range of sheet metal materials—including steel alloys, aluminum, copper, and stainless steel—alongside design support and assembly services, laser cutting and punching, welding, and finishing.

TAIWA can accommodate orders of any size and complexity. We combine competitive pricing for high complexity low-volume runs with cost-saving options for high-volume production, ensuring you receive exceptional value and quality at every stage.

Whether you’re in need of prototype sheet metal parts or high-volume metal fabrication, TAIWA is your trusted sheet metal fabrication provider. Our services encompass:

We help you every step of the way from your initial drawing through to the finished assembled product. Our end to end DFM (Design for Manufacturing) service for custom sheet metal fabrication makes it easy for you to achieve the results you need.

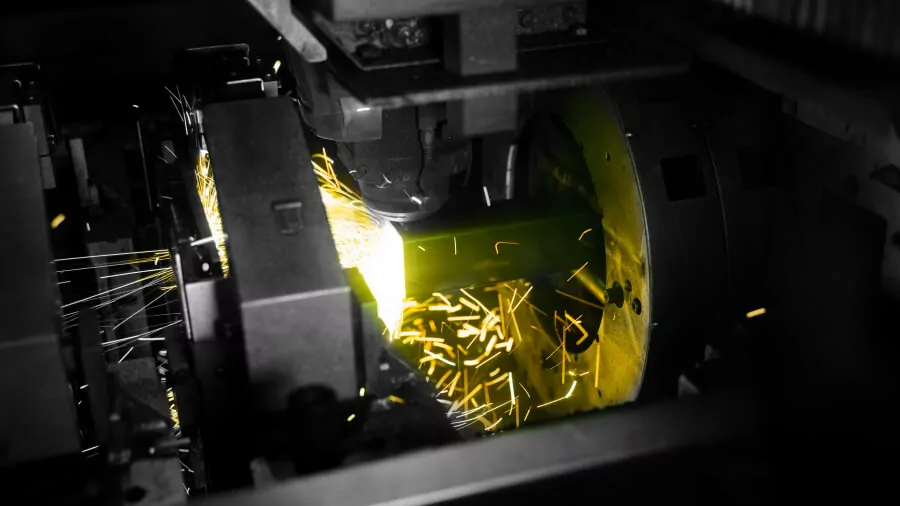

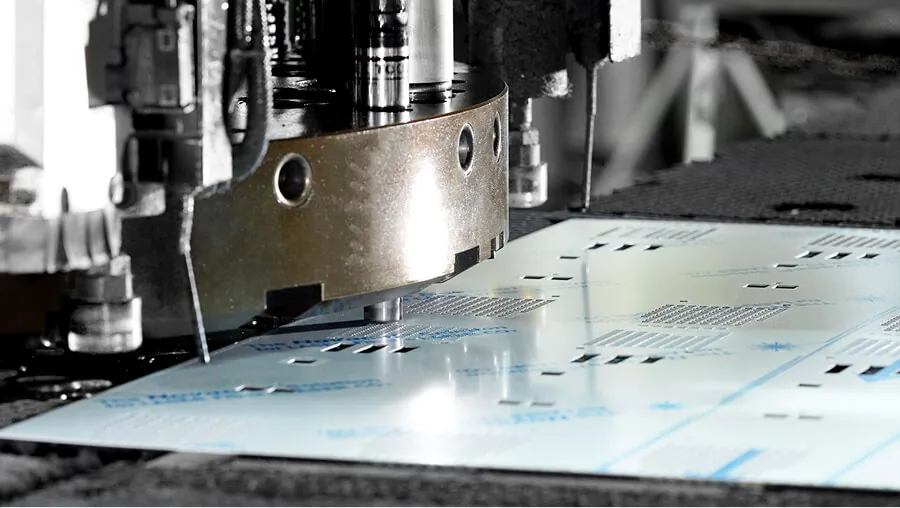

We have a full range of the very latest Japanese laser cutting systems and software for both Fiber and CO2 cutting. We use Amada laser cutting machines capable of handling a wide range of materials including round and square pipe for structural components as well as large sheets.

For projects such as electrical enclosures that require both cutting and punching we have combination Amada systems that complete the cutting and punching in a single set up. This is vital for precision and helps us to control production costs so that you get the best deal.

We use Amada’s cutting-edge simulation software and their HDS and HG series press brakes to deliver unparalleled precision and maintain the aesthetics of our products. Our engineers also undergo over 300 hours of specialized training and obtain Amada certification before managing any client projects.

At Taiwa we use advanced Hitachi welding systems and have expertise in both Argon and CO2 welding of sheet metal and pipe for product components. Each weld is thoroughly inspected and finished to maintain surface quality and aesthetic appeal of each part.

We check and finish every single part to your specifications prior to our assembly team putting it all together, inspecting and finally packaging the products ready to ship to you. Meticulous attention to every detail from the first cut to the final assembly.

Sheet metal fabrication is ubiquitous in modern industry. Its inherent durability, strength, and versatility make it indispensable across all major manufacturing and construction sectors, including automotive and aerospace manufacturing, as well as medical equipment production. Common applications include:

We are competent and highly experienced in sheet metal fabrication using steel, stainless steel, and non-ferrous metals across a wide range of industrial, commercial, and artistic products. The following overview gives some examples of the more commonly used alloys and materials in sheet metal fabrication.

Steel is good for strength and durability, and suitable for stand-alone structures including kiosks and shelters. We provide metal bending, laser cutting services, welding, consultation and design support for precision sheet metal fabrication in steel from our convenient offices in Taiwan.

SS400 structural steel is a hot-rolled steel that can rust easily so is protected with treatments depending on the end use. Taiwa can provide advice to help pick the right surface treatment for any specific SS400 based metal fabrication project.

SPHC-P (JIS G 3131) is a hot rolled steel sheet with an oxide film that needs to be removed from the surface, also known as 'pickled steel sheet'. SPHC-P is a commercial grade steel that is good for structural sheet metal fabrication projects. Commonly used in the automotive industry and for electrical equipment housings.

SPCC (JIS G 3141) is a cold rolled hot steel sheet, which is processed for strength and uniformity. The cold rolling process improves the surface of the steel to achieve a smooth, or polished finish. This steel is typically also a low carbon steel, which makes it easier to draw and achieve an excellent finish in thin sheets that are ideal for home appliances and electrical boxes.

SECC is SPCC cold rolled steel which has been electro-galvanized with zinc to reach an average thickness of electrolytic zinc plating of between 2 and 25 µm. Used for machine covers, machine parts, lighting equipment, building materials, and transportation components.

SGCC is hot-dip galvanized cold rolled steel sheet. This achieves a significantly thicker plating of zinc than the electrolytic process used for SECC, and results in an average plating thickness of 50-100 µm. High rust prevention makes SGCC useful for external machinery like air conditioners, ventilation equipment, and vending machines.

The excellent mechanical properties and versatility of different grades of stainless steel enable us to choose specific stainless steels for improved fire resistance, low temperature ductility, hard wearing surfaces, and different degrees of corrosion resistance depending on the expected use.

SAE 304 & 304L stainless steel (1.4301 & 1.4307) are extremely versatile, also sometimes referred to by the historic name of '18/8' stainless steel due to the nominal composition being 18% chromium and 8% nickel. Commonly used in domestic and commercial kitchen and construction applications where some degree of corrosion resistance is desired.

SAE 316 & 316L stainless steel (1.4401 and 1.4404) are stronger than 304 & 304L with higher corrosion resistance due to the addition of molybdenum to the alloy. Commonly used in saltwater marine applications and where chemical or corrosive material contact is likely.

We are competent and highly experienced in sheet metal fabrication using steel, stainless steel, and non-ferrous metals across a wide range of industrial, commercial, and artistic products. The following overview gives some examples of the more commonly used alloys and materials in sheet metal fabrication.

Aluminum and aluminum alloys come in a range of grades that have excellent corrosion resistance and are very light in weight compared to steel. This makes aluminum a popular choice for sheet metal aerospace components. High heat conductivity also leads to aluminum being popular for kitchen & cooking utensils.

Copper is highly conductive, can be polished to a bright finish, is highly malleable and easily worked into complex shapes. This makes it ideal for decorative and artisanal sheet metal fabrication, and it can be used for decoration on more functional products to improve visual aesthetics.

Powder coating, PVD, galvanizing, electroplating and screen printing are all methods of surface treatment. Some sheet metals have a highly polished finish which may need brushing to reduce reflection, or a customer may want a bright polished finish.

We can provide many different types of surface treatment in different colors to suit any preference for improved durability as well as visual appeal.

With 20 years of experience in precision sheet metal fabrication, Taiwa uses state of the art Japanese AMADA press brakes and AMADA laser cutting and punching combination machines to guarantee extreme precision no matter how complex the design.

For anything from single bespoke projects through large scale mass production, we have the capacity to serve you.

Our extensive library of tooling and forming jigs reduces setup and tooling costs for metal folding and bending, and our efficient modern manufacturing processes are greener due to reduced energy consumption and waste.

We use only the most up to date and advanced Japanese Laser cutting, punching and bending equipment to ensure every part is perfectly produced.

We emphasize the importance of finishing each Sheet metal component and join prior to assembly to guarantee the stable quality of large production runs.

We work with many customers from the design concept phase side by side to ensure the best sheet metal solutions to meet both your budget requirements and your expectations.

Our main fields are sheet metal parts manufacturing for industrial machinery, the optoelectronics industry, electrical control boxes, and metal closures for machinery

We have collected a range of the frequently asked questions from our customers and listed up some of questions and answers. We hope they assist you when starting new sheet metal fabrication.

If you can not find the answer you are looking for, please feel free to contact us by phone, email or contact form. We would be happy to help you in more detail.

Typically, standard quotations are provided within 5 days, while more complex design drawings may require 7-10 days for a comprehensive response.

We accept and work with design files in AutoCAD and SolidWorks formats. For 2D drawings, DWG and DXF formats are preferred, while for 3D drawings, we recommend STP and IGS formats.

We accept sketches, 2D, and 3D files. However, if providing a sketch, there may be an additional charge for computer-aided drawing services.

The lead time for sample production depends on the complexity of the drawing, the completeness of the provided files, and whether surface treatment is required. Typically, it is within 2 weeks. Feel free to contact us for a quotation.

Our company ensures confidentiality through the signing of a Non-Disclosure Agreement (NDA) between both parties. Quotations and communication are conducted through secure email channels. We employ a rigorous electronic drawing system to control and safeguard customer confidential information.

We have a team of 9 mechanical engineers in the design department and 2 product designers.

Find out our latest exhibition and news.

Choosing TAIWA means opting for a sheet metal fabricator that stands by its word to deliver excellence. Our metal fabrication and sheet metal enclosure manufacturing are the core of our extensive service offerings. Connect with us today and experience TAIWA’s expert sheet metal fabricator services.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |