Our controller enclosure designs provide safe and robust physical protection for electronic components used to control a wide variety of devices or systems. Taiwa controller enclosures are engineered with ergonomics and functionality to deliver user-friendly, purposeful design.

Sheet metal controller enclosures can be engineered for any purpose and level of environmental protection. Standard design features include vents, cable and power routing and access points, internal and external racking and mounting boards for components.

Controller enclosures provide an essential service across all types of industries and commercial activities. A fundamental requirement is that controller enclosures should be extremely reliable, durable, safe and easy to maintain and operate.

High quality Taiwa controller enclosures secure and protect valuable and sensitive internal components from damage and optimize both cooling and environmental protection.

Controller enclosures protect sensitive electronic components from physical damage and environmental hazards including dust and moisture. We design controller enclosures to any IP environmental protection rating for specific commercial, industrial or outdoor environments.

Use of specific alloys and finishing materials as well as different closure and assembly methods enable protection from almost any ambient or accidental hazards.

Controller enclosures need to be secure, to prevent unauthorised or unintentional access. They also need to be readily accessible for maintenance, repairs, and upgrades.

When designing a controller enclosure, it is important to specify the level and type of security required to enable the best combination of safe and secure operation with ease of access.

Design elements for temperature regulation, including vents, fans, and heat sinks, along with intelligent panel orientation are used to redirect heat generated electronic components.

Cutouts and removable panels both optimize cooling and make maintenance easier.

During the design consultation with our experienced engineers, we can include customized features for any specific need.

Frequent customized sheet metal fabrication requests include modifications to size and scale, materials, surface finishes and visual appeal, internal and external mounting options, port and control panel configurations.

Industrial control panel enclosures need to provide high levels of protection and serve as an efficient, centralized location for the installation, maintenance and operation of modules and components including power switching and digital control systems.

High security, excellent cooling and environmental protection and effective cable management need to be combined with user-friendly cutouts for routing, ports and rapid maintenance access when designing data center controller enclosures.

More than any other type of controller enclosures, hand held devices require utmost care and consideration of ergonomic features, including smooth, snag-free surfaces and surface finishes. Incorporation of curved sections and rubber inserts are frequently required.

Controller enclosures for medical and dental equipment are often visible to the public. At the design stage it becomes more important to consider the look and feel of the enclosure and focus on an appealing, professional design aesthetic.

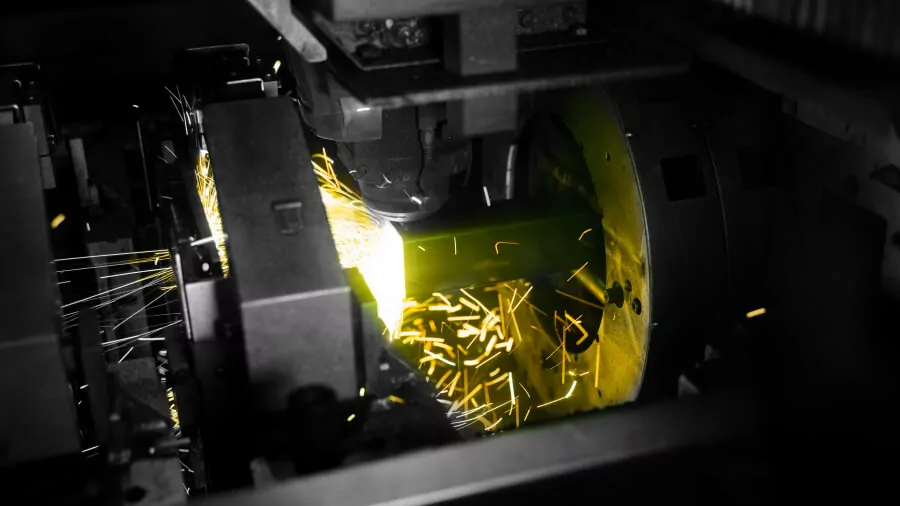

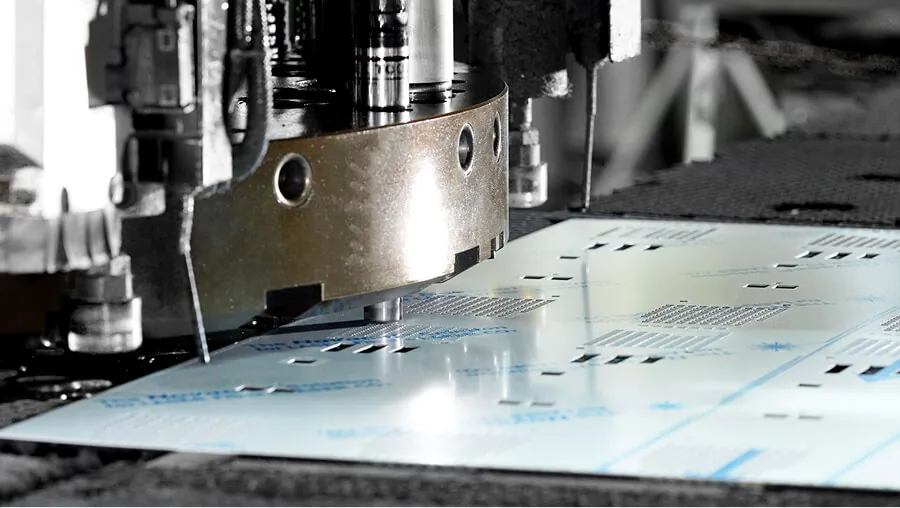

We only use the highest quality AMADA Japanese combination laser punch cutting machines for precision machining in a single pass.

Controller enclosures require high precision, efficient ventilation systems and clean, accurate machining of ventilation slots is essential.

Taiwa maintains an extensive library of tooling and forms that enables us to bend and shape sheet metal into complex and intricate designs without additional tooling.

At the design stage we can optimize your project to minimize or eliminate the cost of manufacturing new tooling.

We offer customized solutions to meet the unique requirements and design specifications of our clients.

Our designs take into account user operability and device functionality, incorporating features such as ergonomic grips, control panel layouts and access.

From initial consultation through design and development to manufacturing and assembly, all stages of project development and production are entirely managed and delivered by our in-house team.

We do not outsource any elements of your project, this ensures that the quality management chain remains unbroken from our first conversation to project fulfilment.

Whether you’re in need of prototype sheet metal parts or high-volume metal fabrication, TAIWA is your trusted sheet metal fabrication provider. Our services encompass:

We help you every step of the way from your initial drawing through to the finished assembled product. Our end to end DFM (Design for Manufacturing) service for custom sheet metal fabrication makes it easy for you to achieve the results you need.

We have a full range of the very latest Japanese laser cutting systems and software for both Fiber and CO2 cutting. We use Amada laser cutting machines capable of handling a wide range of materials including round and square pipe for structural components as well as large sheets.

For projects such as electrical enclosures that require both cutting and punching we have combination Amada systems that complete the cutting and punching in a single set up. This is vital for precision and helps us to control production costs so that you get the best deal.

We use Amada’s cutting-edge simulation software and their HDS and HG series press brakes to deliver unparalleled precision and maintain the aesthetics of our products. Our engineers also undergo over 300 hours of specialized training and obtain Amada certification before managing any client projects.

At Taiwa we use advanced Hitachi welding systems and have expertise in both Argon and CO2 welding of sheet metal and pipe for product components. Each weld is thoroughly inspected and finished to maintain surface quality and aesthetic appeal of each part.

We check and finish every single part to your specifications prior to our assembly team putting it all together, inspecting and finally packaging the products ready to ship to you. Meticulous attention to every detail from the first cut to the final assembly.

Our main fields are sheet metal parts manufacturing for industrial machinery, the optoelectronics industry, electrical control boxes, and metal closures for machinery

Choosing TAIWA means opting for a sheet metal fabricator that stands by its word to deliver excellence. Our metal fabrication and sheet metal enclosure manufacturing are the core of our extensive service offerings. Connect with us today and experience TAIWA’s expert sheet metal fabricator services.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |