Upload your CAD files to get a rapid quotation on custom sheet metal fabrication of prototypes and production parts with lead times as short as a matter of days for simple projects. Discuss your complex and custom sheet metal fabrication requirements with our experienced in-house team and discover how good sheet metal fabrication services by TAIWA can be.

What are our custom sheet metal fabrication services?

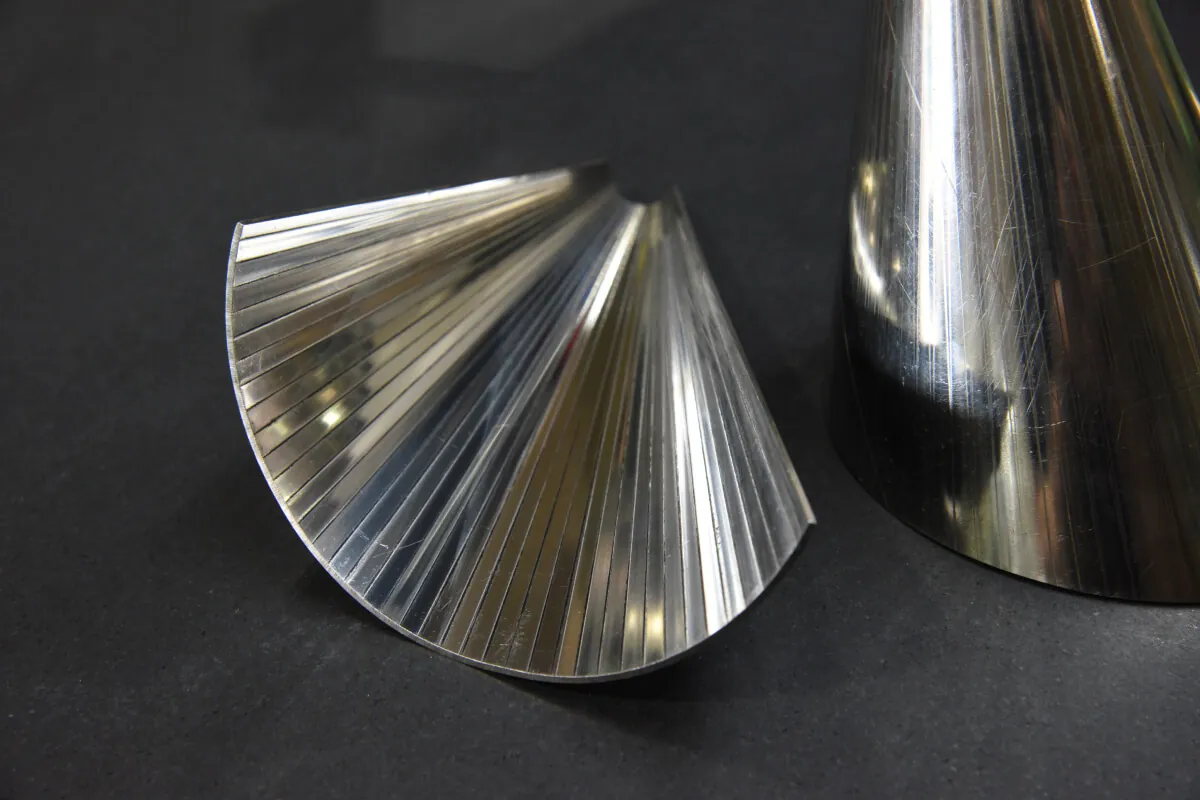

Sheet metal fabrication is a manufacturing process that forms parts and components from thin sheets of metal, which is used by engineers and designers to manufacture durable, high-precision enclosures, brackets and chassis components across a wide range of industries. Taiwan is a sheet metal fabrication centre for global manufacturing of all types of products made of sheet metal alloys, and TAIWA supplies all types of custom sheet metal fabrication services.

How fast & flexible is TAIWA custom sheet metal fabrication?

TAIWA offers a rapid, cost-effective solution for your sheet metal fabrication needs. We can work directly from your 3D CAD files or engineering drawings, and our highly experienced and qualified design engineers can provide you with any level of input you require to ensure the most cost-effective design for manufacturing for your project, with considerable savings possible due to our integrated in-house full service design, fabrication and assembly options.

What materials can I use for my sheet metal fabrication project?

We can manufacture custom sheet metal parts and components in any sheet metal including aluminum, copper, brass and of course steel alloys and stainless steel. With our in-house fabrication and assembly we can install PEM inserts and other forms of joining technologies, as well as high quality welding and finishing for your sheet metal fabrication project. Based in Taiwan, we have immediate access to very high quality sheet metal stock in a comprehensive range of alloys to suit your exact engineering needs.

How big or small can a custom sheet metal fabrication project be?

Whether you want a single prototype, low volume production, mixed prototyping or high volume production run, we have the capability and capacity to devote the same level of expertise and attention to successfully realizing your project requirements regardless of the scale or volume.

What industries rely on custom sheet metal fabrication?

- Aerospace

- Automotive

- Construction

- Defense

- Energy

- Electronic

- Medical & Dental

- Consumer White Goods

Our state of the art manufacturing technology, using the latest Japanese AMADA forming, bending, laser and punch laser combination cutting equipment, enables us to offer highly competitive pricing for custom sheet metal fabrication of low volume prototypes as well as cost savings for high volume manufacturing.

How is sheet metal formed into three dimensional products?

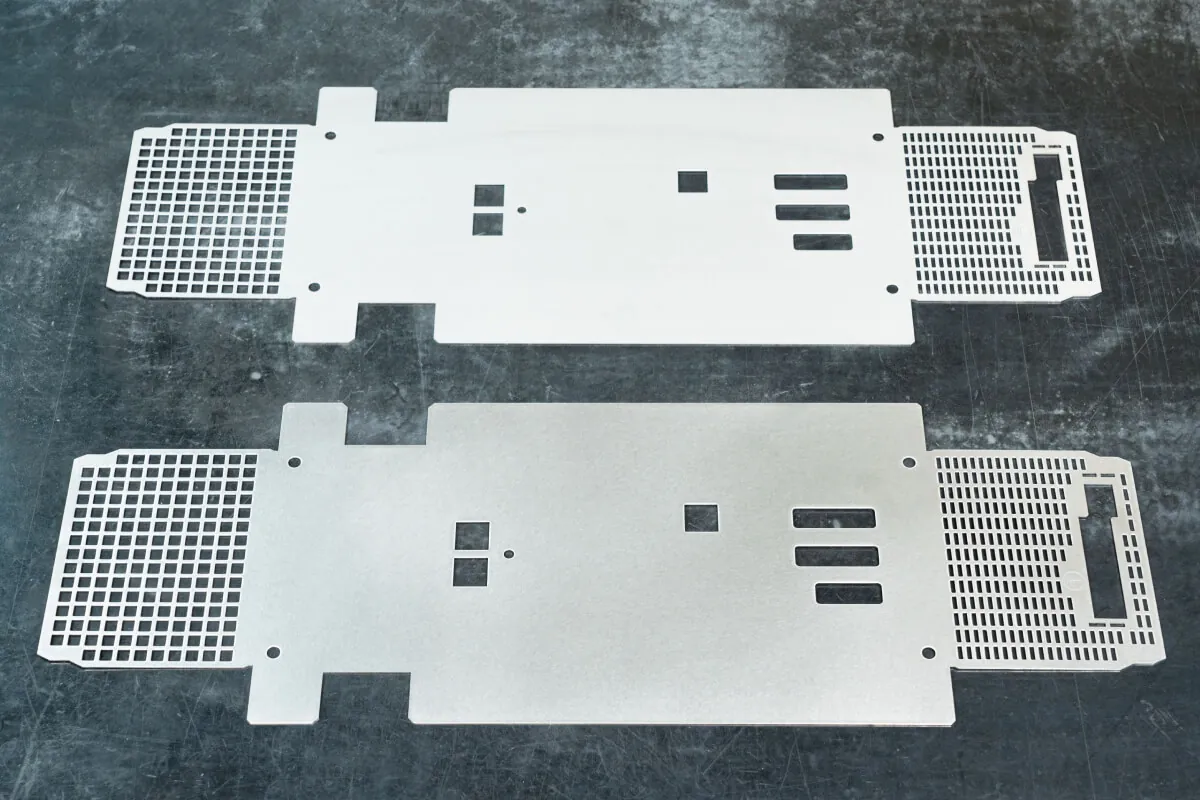

Flat sheet metal stock is formed into its final three dimensional state by a sequence of processes. The first step in any sheet metal project is sheet metal cutting. A shear, laser, or punch press is used to cut the shape that will be formed, including internal holes. The initial sheet metal cutting process is called blanking and produces a flat sheet metal blank that will be progressively formed into the final shape by a series of additional steps..

The next step is to form the sheet metal blank by sheet metal bending. A press brake is the standard equipment used for bending sheet metal, and can be manual or automated. At TAIWA we use Japanese AMADA computer controlled press brakes to have complete control over the bending process. The AMADA press brake enables us to calculate spring back and stresses virtually before bending. This increases accuracy and durability of the finished product.

Press brakes use tooling in the form of dies that are inserted into the machine that provide the form for angular bends of specific radius and shape. The press brake forms the two-dimensional sheet into a three-dimensional object by bending the sheet around the die. Sheet metal forming can create simultaneous bends in different directions, this enables forming simple shapes like brackets as well as complex custom sheet metal fabrication parts.

Making new tooling dies for press brakes is expensive, but once you have the tooling dies for your press brake, making more sheet metal parts that require the same die becomes less expensive, and this makes sheet metal fabrication a very cost-effective choice for high volume production. For low volume production, the cost of tooling can be a significant proportion of the cost, so it is best to work with a sheet metal fabricator who has an extensive library of tooling dies of different radius and shape and modify your design to fit the available dies.

How does TAIWA custom sheet metal fabrication work?

TAIWA is a full-service, vertically integrated custom sheet metal fabrication service provider. This means that we have expertise, equipment, and tooling dies to carry out all stages of the design and manufacturing process of your custom sheet metal fabrication project. We are based in Taiwan, which is a perfect location for a global sheet metal fabrication service due to the excellent sheet metal supply chain for quality materials, rapid and efficient global shipping services and co-location of high technology engineering and manufacturing services.

What are the benefits of sheet metal fabrication?

- Sheet metal can be given a wide variety of finishes including printed designs

- Metal alloys are tougher and more durable than plastics

- Can be designed for high temperature uses

- Cost efficient to manufacture in high volume production

- Flexible design and fabrication characteristics make sheet metal suitable for a wide range of products

- Can be manufactured with precision to exact engineering requirements

When we receive your enquiry, we offer our expertise in design for manufacturing to help you optimize your project for the best possible results in the material of your choice. We convert the completed CAD design into code to programme our AMADA combined sheet metal punch / laser cutting machines to make the sheet metal blank. Then our skilled operators will form the blank into the desired shape using press brakes with the correct tooling.

We have punch machines that are designed for fitting inserts as well as a fully equipped welding workshop with both manual and automated processes for joining formed sheet metal parts together. Our finishing services include PVD, powder coating, brushing, polishing and screen printing to achieve any combination of durability and style that you require. We also have an in-house assembly shop for building your completed project to maintain our exacting quality standards throughout the entire production process.

TAIWA: custom sheet metal fabrication with expert advice

Our design, manufacturing, assembly and shipping services can help you find the best solution for any custom sheet metal fabrication project. Our systems meet international quality standards, using advanced AMADA CAD/CAM design software to precisely model every bend digitally in advance to allow for deformation and spring-back, which reduces prototyping time and development costs.

- Expert, comprehensively trained designers & machine operators

- Friendly customer service & skilled engineering support teams

- All our machine operators have completed at least 300 hours of training and passed relevant examinations

- TTQS Workforce Quality Certification (Taiwan)

- ISO 9001 & ISO 14001 certified

- Extensive library of dies & tooling reduces set up costs

- Precision Japanese AMADA cutting, punching & forming machines

- Material technology expertise

- Skilled assembly team with capabilities for complex products

- Long standing expertise in design for manufacturability

TAIWA has 20 years of experience in precision sheet metal fabrication using state of the art Japanese AMADA press brakes and AMADA laser cutting and punching combination machines to guarantee the success of your project. . We deliver extremely precise results, no matter how complex the design.

- Capacities up to 3000 mm sheet length

- 0.3 mm to 20 mm sheet thickness

- Flatness maintained to 0.2 mm

- Verticality within 0.15 mm

Our large inventory of dies, tooling and forming jigs reduces setup costs for metal folding and bending, and our efficient modern manufacturing processes are greener due to reduced energy consumption and waste. Contact us to find out how our sheet metal fabrication services can help you complete your sheet metal design with ease.