Sheet metal enclosure boxes for electronics are the preferred option for commercial and industrial electronics manufacturers for several reasons. Offering unbeatable protection for sensitive components and efficient production benefits at any scale of manufacturing, metal enclosure boxes for electronics are likely to remain the standard way of protecting valuable and delicate components for years to come.

How are metal enclosure boxes for electronics manufactured?

Manufacturing metal enclosure boxes for electronics has two main stages, cutting out and folding. Depending on the complexity of the design being manufactured there may also be a need for fitting mounting brackets and threaded barrels for internal components. There will also be some final assembly and finishing that takes place along with quality control measures to ensure that the finished result matches the design specifications.

Marking & cutting out sheet metal enclosure boxes for electronics

Marking and cutting out sheet metal enclosure boxes for electronics is an important stage in the manufacturing process. Non standard sheet sizes are more expensive, and if you are working in stainless steel the material costs can be a significant proportion of the total cost of the project. The video above shows an advanced combination laser punch cutting machine cutting out the blank for a metal enclosure box for electronics.

At the design and specification stage, it’s a good idea to talk to our experienced sheet metal fabrication engineers. If you are not familiar with standard sheet sizes and pricing you may be surprised how much you can save by minor modifications to your design that enable it to fit more efficiently onto a standard sized metal sheet.

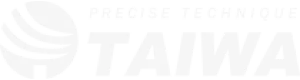

Precision cutting of the sheet metal blank is essential

The picture above shows a single sheet metal blank that will be folded into an enclosure box for electronics. You can see how the combination laser punch cutter has made the slots and perforations in the blank with high precision. This sheet metal box is being fabricated from stainless steel, and the protective film will now be removed before the next stage, which is folding the sheet metal into the final box form.

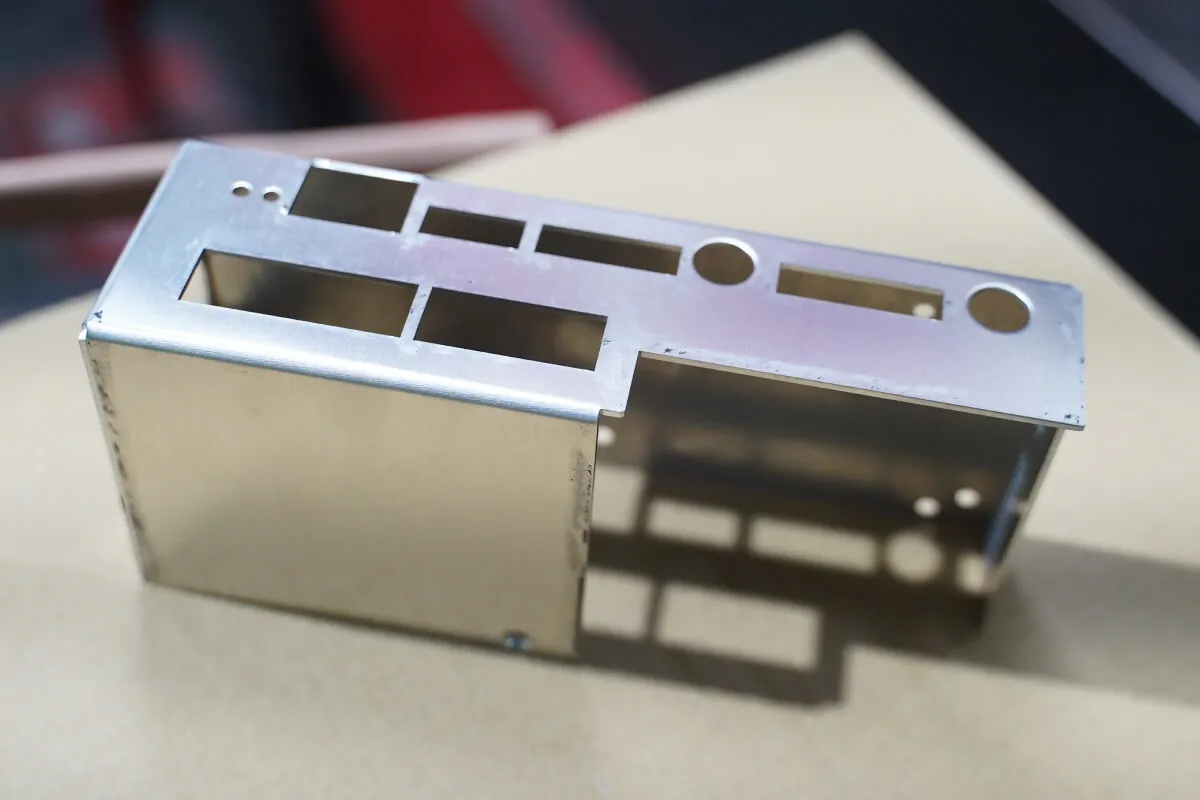

Folding sheet metal enclosure boxes for electronics

The next major stage in this project is folding the sheet metal blank into the desired shape of the enclosure box for electronics. Before folding, the protective film is removed and if necessary the edges of the blank may be lightly buffed to make them less sharp if it is considered that they may be a hazard to people who will be using the box in the future. You can see that the technician in the photo above is wearing protective gloves for this reason.

Computerised metal folding includes important spring back calculations

Multiple folds are required to create a finished sheet metal enclosure box for electronics, and one of the most important capabilities of a sheet metal enclosure fabricator is to be able to accurately bend and fold sheet metal with high precision. This is not easy, as all metals resist folding and have a characteristic called ‘spring back,’ which is the degree to which they will ‘unfold’ a little after bending. Advanced sheet metal fabrication technologies include computerised systems that calculate the increased bend required to ensure the metal stays in the correct position.

Talk to Taiwa about making your metal enclosure boxes for electronics

All the examples above come from our manufacturing process, and real clients looking for high quality sheet metal fabrication. Not all cutting and bending technologies are the same, and our use of integrated AMADA machines for cutting and folding increase our production efficiency and precision at any volume. Our in-depth ODM capabilities make it easy to work with us to build your project even if you have limited experience of sheet metal fabrication.

We have the capabilities to manufacture sheet metal products at any scale, from street furniture to promotional merchandise. Contact us to discover high quality sheet metal fabrication that is also surprisingly cost-effective because of our adoption of highly efficient modern technologies at our integrated manufacturing facility in Taiwan.