Metal enclosure boxes for electronics need to be precision manufactured with close fitting edges and perfectly located component mounting positions, ventilation perforations, slots and access ports. In this case study, Taiwa demonstrates the capabilities and technology to manufacture cost effective, high quality metal enclosure boxes for electronics to suit any production volume or customization requirements.

How does Taiwa cut and fold metal enclosure boxes for electronics?

In this case study we’re going to see how Taiwa efficiently manufactures sheet metal enclosure boxes for electronics using high precision cutting and advanced bending technology and techniques. Even something apparently as simple as a rectangular metal box fabricated using a cut and fold process requires a surprising level of skill and capabilities to manufacture quickly and efficiently, keeping costs down and improving customer satisfaction.

Why is cutting technology important for sheet metal enclosure boxes for electronics?

Cutting technology is important for sheet metal enclosure boxes for electronics as better technology reduces waste, increases precision, and speeds up production, all of which save costs and improve quality. Ideally your design should use as much of a standard sized sheet of metal as possible, and all holes, slots and apertures should be made in a single pass of the cutting table.

Non standard sized sheets cost more, so you should definitely check with our design engineers for ways to tweak your design to fit more on a sheet, especially if you are working in stainless steel or non ferrous metals where there are fewer sheet size options and metal sheets are more expensive.

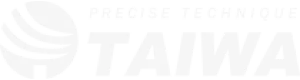

At Taiwa we use Japanese AMADA combination laser punch cutters, as you can see in the video above, to cut out the blanks that will be folded into sheet metal enclosure boxes for electronics. There are several advantages to working with a company like Taiwa that uses very high precision, single-pass technology for cutting and punching. Single pass cutting and punching is quicker and cheaper than multiple passes, and maintains accurate registration so there are no problems with misalignment of holes and slots, which can make it impossible to assemble the box.

How does Taiwa ensure precision folding of metal boxes for electronics?

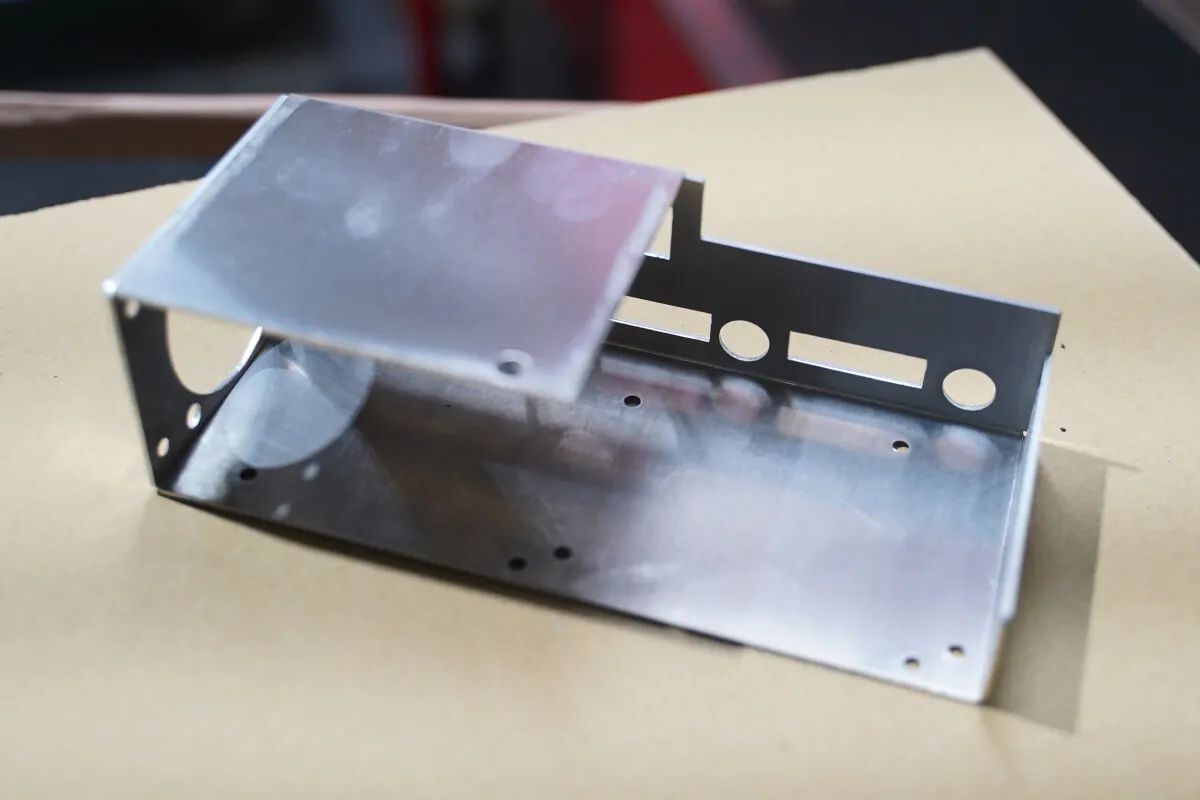

To achieve precision folding of the 90 degree right angles that are needed to make these metal boxes for electronics, we had to bend the sheet metal slightly past 90 degrees, so that after spring back the result was exactly what was required. Our AMADA folding machines have built-in computers that predict spring back angles for the thickness and type of sheet metal being used, reducing the number of manual calculations required, improving accuracy and speeding up the folding process.

The finished metal enclosure box demonstrates the accuracy and precision of Taiwa sheet metal fabrication. Every single completed unit has exactly the same dimensions, and is now ready for any type of finishing that our client might want. We offer powder coating, painting, printing and engraving to customize the look and feel of your sheet metal design.

Taiwa manufactures metal enclosure boxes for electronics

Taiwa uses Japanese AMADA sheet metal fabrication technology for cutting and bending to efficiently manufacture sheet metal enclosure boxes for electronics at any volume, from single bespoke projects to mass production. We are extremely good at building partnerships for ODM, and are happy to bring our design and engineering skills to the table if you have a sheet metal enclosure project but do not have prior experience or in-house expertise.

Our use of the latest and best technologies is part of our commitment to quality sheet metal fabrication that can be seen in our wide range of successful products, from street furniture to promotional merchandise. Contact us to discover how Taiwa provides effortless access to efficient, cost-effective manufacturing of your next sheet metal project.