Successful sheet metal fabrication requires an understanding of the process and range of sheet metal fabrication techniques starting at the design stage. This is especially important in complex sheet metal fabrication projects that require a good understanding of design for manufacturing principles to make them cost-effective in 2025, or even to make it possible to manufacture them at all in sheet metal!

What is Design for Manufacturing (DFM)?

Design for manufacturing, also called Design for Manufacturability (DFM), is a set of principles that you should follow to make your design easier to manufacture. There are some best practices and design principles for all forms of manufacturing process that will give you the best results. Some of these are limitations of the manufacturing process, and others are recommendations to reduce stresses and failures – like the minimum distances between features when making cuts in sheet metal and ensuring metal deformation does not exceed physical limits.

Minimum Material Thickness (MT) Distances Between Features For Laser Cutting

- Hole to Edge Distance = 2X MT or 0.125”, whichever is smaller

- Hole to Hole Distance = 6X MT or 0.125”, whichever is smaller

- Minimum Relief Cuts = 0.010” or 1X MT, whichever is greater

- Minimum Corner Fillets = 0.5X MT or 0.125”, whichever is smaller

- Minimum Tab Thickness = 0.063” or 1X MT, whichever is greater

- Minimum Slot Thickness = 0.040” or 1X MT, whichever is greater

Alongside design for manufacturing, there are cost considerations with manufacturing in sheet metal, which can influence the manufacturability of your design by making it unrealistically expensive to make. Using standard sheet sizes and press brake tooling will speed up manufacturing and reduce tooling costs if cost-effectiveness is an important feature of your design. If cost is no problem, then the only limits to your imagination are the practical limitations of cutting, bending, joining and assembly of sheet metal in your chosen material and gauge.

How do you design a complex sheet metal product for manufacturing?

At the design stage of a complex sheet metal fabrication product you need to consider how your design will need to be processed to complete it, and how complex the techniques required will be. Even if you only need simple sheet metal cutting, forming, bending, and joining to make your design, following the best practice principles for DFM will help reduce costs and improve the end result. Following the following suggestions will help you to keep costs down and increase the quality of your sheet metal fabrication project.

Use a vertically integrated sheet metal fabrication provider

Keeping all manufacturing processes in one place is a very simple method of increasing the manufacturability of your design. If cutting, bending, forming, joining and assembly are all being carried out in the same facility by the same fabrication service provider it makes it easy to maintain high quality standards. If possible ensure that you work with a vertically integrated sheet metal fabrication provider who can guarantee all stages of the manufacturing process.

Use standard sheet metal gauges where possible

Sheet metal can be supplied in almost any thickness and alloy, especially in Taiwan, where high quality engineering is a way of life! There are however standard gauges that are more commonly used than others, and sheet metals in these gauges will be cheaper to buy and easier to find for rapid project turn-around. It is also more likely that your sheet metal fabricator may have forming and bending dies in their tooling library that are made for standard sheet metal gauges, reducing the need to manufacture tooling, and the additional costs that entails.

Make sure all manufacturing features are in the design file

This is a common problem in DFM. For example, notches and slots should have their width defined in the design file, even if the slot width is the same as the kerf thickness of the process used to cut the sheet. This ensures the slot will be in the correct position.

Be aware of the additional limitations of working with thicker gauges

The cutting tolerances of thicker sheet materials are an additional factor when calculating laser cutting or punch cutting tolerances, because increased thickness changes the characteristics of the cutting process. For thicker sheet metal stock and non-standard gauges it’s important to check with the sheet metal fabricator to get precise tolerances for your design. Also remember that thicker materials are usually not available as standard stock in large sheet sizes.

Common Uses of Sheet Metal Fabrication

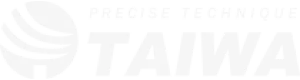

The versatility of sheet metal fabrication enables designers to make anything from the smallest washer to entire buildings out of sheet metal. At TAIWA we have made products including coffee roasters and bus shelters as well as high quality electrical and computer enclosures. Because of this versatility, there are a very wide range of products and industries that make extensive use of sheet metal and custom sheet metal fabrication to manufacture their products.

- Electrical enclosures

- Electronic cases & chassis components

- Power cabinets

- Busbars & electrical components

- Boxes & brackets

- Metal sinks & culinary equipment

- Automobile components

- Airplane parts

- Home appliances

- Industrial & commercial furniture

- Safety screens, fencing & barriers

Sheet metal comes in thickness from light foils to thick structural plate, and can be made from steel alloys, aluminum, copper, tin, brass, nickel, titanium or even gold and silver. Sheet metal stock can also come in a variety of finishes and styles including plain sheets, corrugated and perforated sheets.

Sheet metal fabrication is not like other processes

When designing in sheet metal, it’s good to keep in mind that it is neither an additive process, like 3D printing, or a subtractive process, like CNC machining. The limitations of strength and size that come from the choice of sheet size and sheet gauge stay with you through the design process, and are not easy to change by simply adding more thickness or cutting away excess material once your design becomes three dimensional.

9 Common-Sense Rules for Designing a Complex Sheet Metal Fabrication Project

- You can’t make an entirely closed box using a press brake

- You can join parts together by welding or riveting if your design becomes too complex

- You can’t easily increase strength by adding sheet thickness

- You can add PEM inserts and component brackets to locally increase strength

- Features must be kept away from bends to reduce distortion

- A uniform bend radius is much cheaper to make than a variable bend

- Thin materials are more difficult, and expensive, to weld than thicker materials

- If using expensive sheet stock, lay out component designs to maximize sheet use and minimize waste

- Work with an experienced fabricator who can check your design for issues, and help fix them!

What type of sheet metal will you use?

Different metal alloys are available in most sheet metal gauges here in Taiwan for precision sheet metal manufacturing. When deciding on the metal you want to use for your sheet metal fabrication project, you can select specific metals for strength, durability, ease of bending and welding, corrosion resistance, visual appearance, weight and cost.

Stainless steel

Standard and spring-steels are both used in sheet metal fabrication. The most common stainless steels are the 300 series, which are non-magnetic. 304 and 316 stainless steel are industry standard alloys that are available in a wide variety of gauges and sheet sizes, making them excellent for corrosion resistant culinary and marine applications in particular.

400 series stainless steels are magnetic, and have lower corrosion resistance than 300 series stainless steel, but are also less expensive. 410 is heat treatable and 430 is commonly used in brushed stainless steel finished appliance casings and surfaces. All stainless steels are elastic rather than plastic when deformed, so need to be bent beyond the desired profile to allow for spring-back.

Spring stainless steels work harden and become brittle so need to be heated when formed to avoid stress fracturing. 301. 1075, 1095 and 17-4 stainless are standard grades of spring steel, and require significant over bending to achieve any desired profile. Computer assisted bending machines are essential for rapid, accurate work in stainless steel as they can be programmed to calculate the exact overbend required for any gauge and bend radius.

Non-stainless steels

Cold rolled steel (CRS) and pre-plated steels are the most commonly used sheet metal stock for sheet metal fabrication. They are very cost-effective and pre-plated steels with hot-dip galvanizing, electroplating or annealing have corrosion resistance that is suitable for most household, commercial and light industrial applications. Cold rolling of steel is used to flatten out the finish of hot rolled steel and give tighter tolerances when formed. 1008 and 1018 are the most commonly used CRS alloys.

Aluminum

Standard aluminum sheet alloys are inexpensive and very light, strong and resistant to corrosion. This makes them attractive for many custom sheet metal fabrication projects. Advanced aluminum alloys are available which have exceptional strength to weight ratios suitable for aerospace applications and other uses where strength with light weight are extremely important.

Copper & brass

For “red” metal finishes, engineers and designers may specify electrolytically tough pitch (ETP) copper in grades C110 or C101. For a more golden color, cartridge brass is a less common alternative. Copper and brass alloys can be very useful for decorative sheet metal components, but may need finishing to protect them from oxidation and discoloration.

Titanium & exotic alloys

Custom sheet metal fabrication in exotic steel alloys, like monel or hastalloy, or using titanium is highly specialized and may require special equipment, especially for effective welding of components. In some marine, aerospace and defense applications, exotic alloys and titanium are very important where high strength, temperature and corrosion resistance are required.

How do you select the right finish for your sheet metal fabrication project

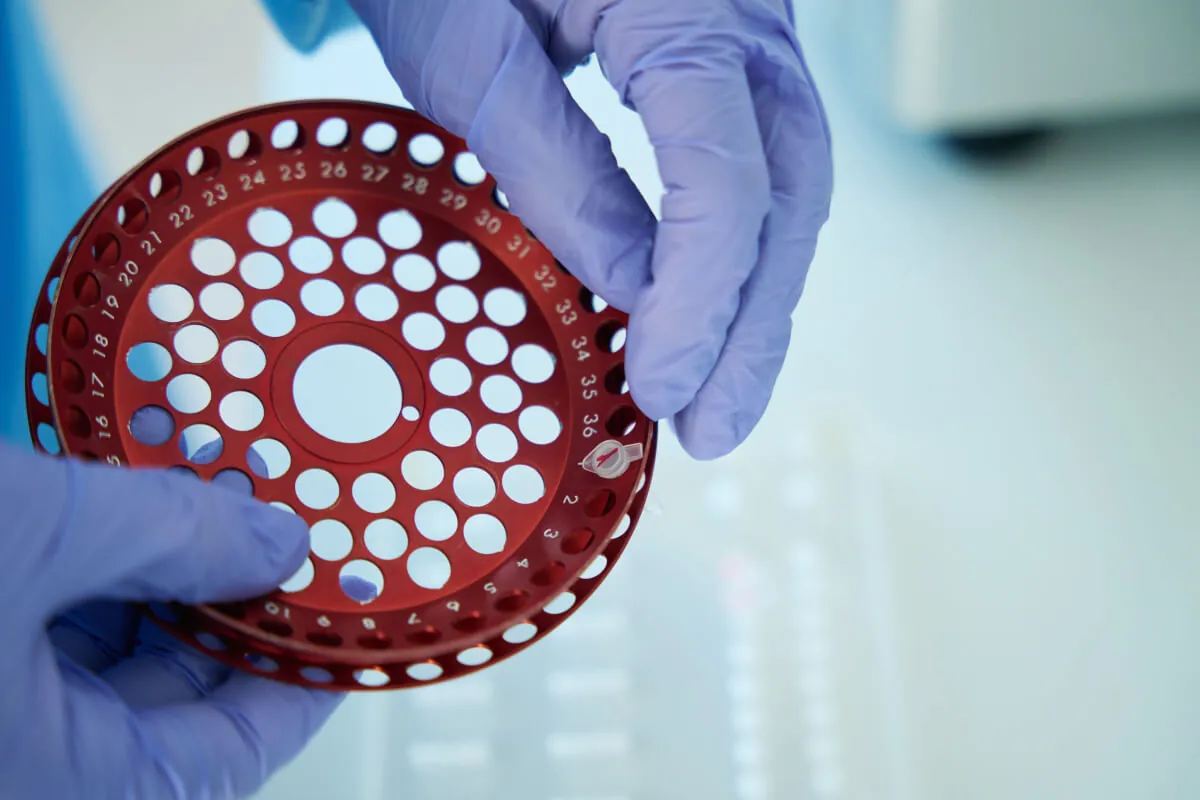

Sheet metal finishes can be classified into protective and aesthetic finishes. Some finishes are both protective and aesthetic, like anodizing and PVD. Some treatments are additive, applying a coating or process to transform the surface of the metal, others like sandblasting or brushing are simply transformations of the sheet metal surface. The smooth anodised finish of the medical centrifuge component pictured above is easy to keep clean and makes it easier to read the numbers embossed into it.

Which sheet metal finish you select will depend on your design requirements, the only significant design for manufacturability consideration is in making sure the finish is applied at the right time in the sheet metal fabrication process. This is specifically an issue if you are including inserts, which may or may not be compatible with different finishing types – you can always ask us at TAIWA if you have any doubts about compatibility!

Choose the right sheet metal fabricator

The process of sheet metal fabrication begins with a functional choice of sheet metal as the best way to manufacture your product. This choice influences the design because of the considerations, strengths and limitations of using sheet metals. You need to make some complex decisions to balance utility, aesthetics, strength, durability and cost, and that’s all before you test your design by prototyping.

There are very few sheet metal products that can be designed and manufactured without prototyping, and this is usually restricted to very well understood, very simple designs like basic boxes and enclosures, or sheet metal cladding panels. Even then, the use of CAD enables virtual prototyping to reduce the likelihood of costly errors.

At TAIWA we make it easy for you to create, prototype, and test your sheet metal design, and to manufacture low volume, custom, and high volume production components and finished products. Our vertically integrated sheet metal fabrication service assists you at every stage from design to assembly and shipping, and our continuous quality control systems ensure that every sheet metal product is manufactured to the exact specifications you want. Contact us to discuss how to create the best possible, most cost-effective, real-world version of your design.