Taiwa electrical control boxes for machinery are designed and engineered to provide excellent physical protection for high and low voltage industrial, commercial and domestic applications. Functional ergonomic features ensure safe operation and facilitate upgrades and maintenance access.

Electrical control boxes can be engineered for any operating conditions and designed to achieve any level of environmental protection against water ingress, dust, chemicals and solvents. Custom sheet metal fabrication of electrical control boxes makes them suitable for any industrial, commercial or domestic use.

Our in-house expert design engineers can integrate any features you require, including cooling vents, fans and heatsink mounts, cable channels, power routing and maintenance access panels. We can also include design compatibility for standard and custom industrial racking systems and mounting points for PCBs and other components.

Electrical control boxes are essential, standard, equipment for managing a wide range of industrial machinery and commercial equipment with different power and duty cycle requirements. Electrical control boxes need to provide a durable, safe and reliable environment from which to manage the operation of machines and ancillary equipment, and should be maintenance friendly and easy to operate.

Taiwa are the perfect choice for sheet metal electrical control box manufacturing because of our extensive experience in sheet metal fabrication and integrated design, manufacturing and assembly processes, which maximize quality control and efficiency.

Electrical control boxes need to protect electrical switch gear and electronic components from physical and environmental hazards including dust and moisture.

Specific alloys, finishing methods, closure and assembly systems can be customized at the design stage to reach any IP environmental protection rating for specific commercial, industrial or outdoor applications.

Electrical control boxes need to be easy to use, but also physically secure against tampering, and designed to maintain a safe, insulated, distance between electrical systems and human operators.

It is also necessary to include access for maintenance, repairs, and upgrades. Safety, security and ease of maintenance and operation are all features that can be factored into the design stage of Taiwa electrical control boxes.

During the design stage, our engineers can assess the cooling and maintenance requirements of your electrical control box and work with you to ensure that efficient temperature regulation is included in the design.

Vents, fans, heat sinks, and panel orientation redirect heat away from electronic components. Removable, vented access panels can both optimize cooling and improve maintenance access.

Our extensive experience in sheet metal fabrication of commercial, industrial and artistic designs means it is very unlikely that you will have a customization requirement that we cannot satisfy.

Our design engineers can rescale your project, change materials, finishing options and also provide insight and design support for all types of fastener, fixing, panel, switch, cut-out and panel styles and features.

Industrial electrical control box manufacturing requires close attention to durability, environmental protection, electrical safety and maintenance.

Industrial electrical control boxes usually have security measures built into the design to prevent unauthorized access and enable lock-out of connected machinery and systems to protect people engaged in cleaning, maintenance or repairs.

Electrical control boxes for commercial use usually require similar features to industrial electrical control boxes, and may require water or dust proofing as well as tamper proofing if publicly accessible.

Attention to visual appearance and ease-of-use features is necessary for control boxes being used in places they are visible to the public or commercial customers, like offices, shops and service centres.

Similar to commercial electrical control boxes, domestic control boxes for electrical equipment need to be safe, with the added requirement of being tamper proof to a level that protects children and people who have no electrical competency but need to use electrical control boxes to manage domestic refrigeration, heating, cooking, car chargers and other commonly found domestic electrical equipment.

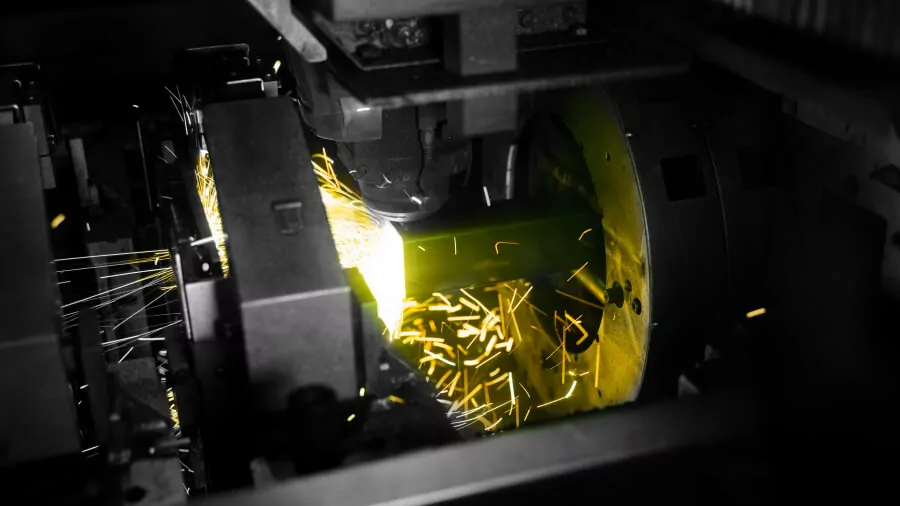

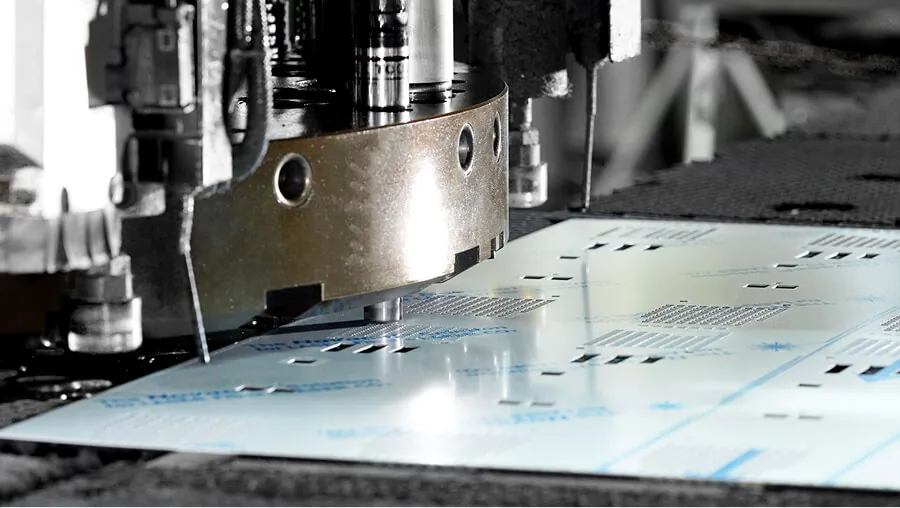

We use AMADA Japanese combination laser punch cutting technology to facilitate high precision single pass preparation of sheet metal components ready for forming or assembly.

Electrical control boxes depend on clean, accurate punching and cutting for effective cooling ventilation slots, precision assembly and inclusion of internal racks, fixing and mounting components.

Because of our extensive experience manufacturing a wide range of custom sheet metal products for industrial, commercial and artistic uses, we are likely to have existing tooling that can be used for your project.

Our engineers are expert in design customization of complex bends and features using available tooling without requiring additional tooling. This avoids a ‘hidden’ cost of many sheet metal fabrication projects.

At Taiwa, we are always ready to apply our long experience and established expertise to assist in building elegant, efficient, expert design solutions for our customers.

No matter how simple or complex your electrical control box project, we apply comprehensive, thorough, design engineering to create the most effective solution.

Taiwa is a vertically integrated company, with all stages of design, engineering, manufacturing and assembly being managed on-site at our production facility in Taichung, Taiwan.

This makes it easy for us to integrate quality management systems that guarantee every stage of the production process and ensure the final product exactly matches our customer requirements.

Whether you’re in need of prototype sheet metal parts or high-volume metal fabrication, TAIWA is your trusted sheet metal fabrication provider. Our services encompass:

We help you every step of the way from your initial drawing through to the finished assembled product. Our end to end DFM (Design for Manufacturing) service for custom sheet metal fabrication makes it easy for you to achieve the results you need.

We have a full range of the very latest Japanese laser cutting systems and software for both Fiber and CO2 cutting. We use Amada laser cutting machines capable of handling a wide range of materials including round and square pipe for structural components as well as large sheets.

For projects such as electrical enclosures that require both cutting and punching we have combination Amada systems that complete the cutting and punching in a single set up. This is vital for precision and helps us to control production costs so that you get the best deal.

We use Amada’s cutting-edge simulation software and their HDS and HG series press brakes to deliver unparalleled precision and maintain the aesthetics of our products. Our engineers also undergo over 300 hours of specialized training and obtain Amada certification before managing any client projects.

At Taiwa we use advanced Hitachi welding systems and have expertise in both Argon and CO2 welding of sheet metal and pipe for product components. Each weld is thoroughly inspected and finished to maintain surface quality and aesthetic appeal of each part.

We check and finish every single part to your specifications prior to our assembly team putting it all together, inspecting and finally packaging the products ready to ship to you. Meticulous attention to every detail from the first cut to the final assembly.

Our main fields are sheet metal parts manufacturing for industrial machinery, the optoelectronics industry, electrical control boxes, and metal closures for machinery

Choosing TAIWA means opting for a sheet metal fabricator that stands by its word to deliver excellence. Our metal fabrication and sheet metal enclosure manufacturing are the core of our extensive service offerings. Connect with us today and experience TAIWA’s expert sheet metal fabricator services.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |