Custom sheet metal fabrication of electrical equipment cases and electrical equipment enclosures is an excellent choice for manufacturing robust, high quality cases and cabinets that are suitable for a wide range of commercial and industrial applications.

We make it easy for you to protect your important and sensitive electrical and electronic equipment from environmental hazards in secure, temperature controlled sheet metal cases.

From sterile enclosures for medical equipment to safety conscious high voltage equipment cabinets, electrical equipment cases and enclosures require careful attention to functional details from the very beginning of the design and manufacturing process.

From cooling vents to internal racking and mounting points, secure cable channels and access points, we make sure no detail is overlooked.

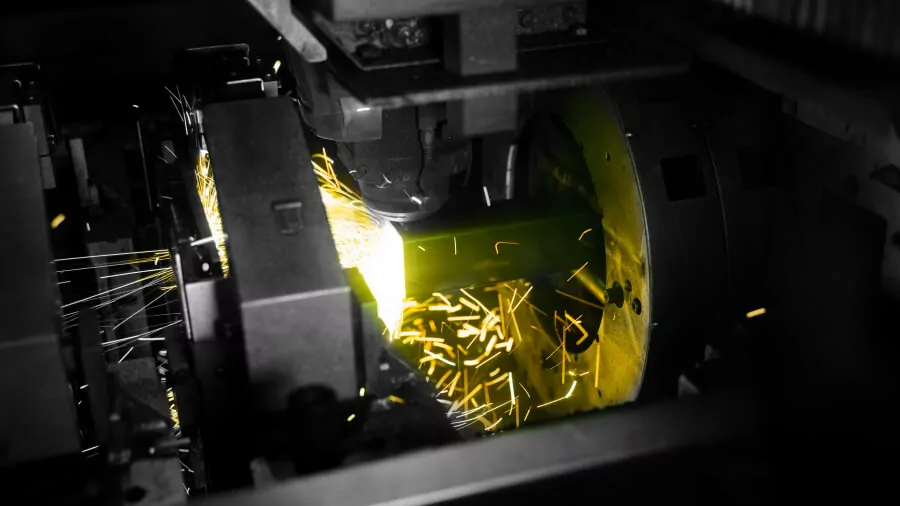

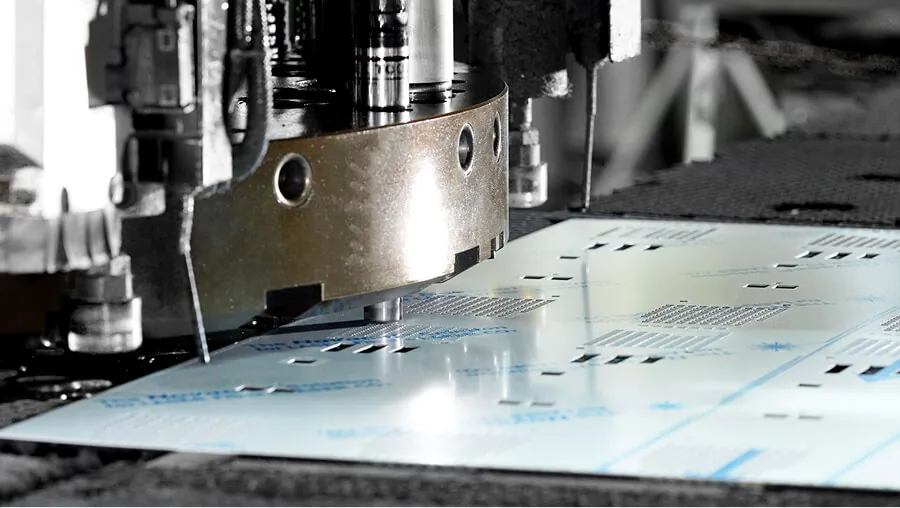

Taiwa custom sheet metal fabrication has the precision and expertise to manufacture high quality electrical equipment enclosures and cabinets to match any size or configuration required. We employ on-site Japanese AMADA cutting and forming technology, precision welding and expert assembly systems to ensure the quality of the results matches the quality of your design vision.

We pride ourselves on our vertically integrated approach to custom sheet metal fabrication, which combines our long history of design and development of standard and customized products for our global customer base with our established expertise and the professional standards we apply to every step of the production process, from initial consultations with our clients through to production and dispatch.

Equipment cases and machinery cabinets can be manufactured from a variety of high quality materials depending on the engineering and design requirements.

Sheet metal options include SPCC, SUS, SECC, Aluminum, SGCC and Copper. We can add coatings, printing and surface finishes to enable any combination of design, functional durability and eye-catching visual appeal.

Structural strength can be built into the design either by adjusting material thickness, between 0.5mm and 5mm or by including webs, framing, folds and hems to add rigidity to key locations.

Our expert design and engineering team can help you achieve the strength you need with the weight and finish your require by careful optimization of design and material features.

Electrical equipment enclosures can be completed by any combination of welded assembly and use of fasteners and fastening methods. This applies to exterior assembly and internal racks, components, equipment and board mounts. We apply our experience in designing and manufacturing distortion free sheet metal structures to advise on the use of screws, bolts, slots, tabs and welded assembly to eliminate distortion and maintain excellent finishes and visual appeal.

The quality of assembly has a major impact on the construction quality and visual appeal of any electrical equipment enclosure. Professional in-house assembly by a sheet metal fabricator is always going to achieve better results with proper quality control measures than outsourced or third-party DIY assembly. This is why Taiwa maintains a fully equipped assembly line alongside our fabrication lines and offers an integrated, quality controlled, fabrication and assembly service.

An advantage of choosing Taiwa for your electrical equipment enclosures, hi-fi cabinets and specialist component cases is our total commitment to quality. We take the utmost care of your project from our first discussions of scope and requirements through to dispatch of completed products, after sales service and support. We focus on ensuring you get the results you want that meet your exact requirements.

Quality in custom sheet metal fabrication has to be valued and monitored at every stage of the process to ensure success. Taiwa’s vertical integration of customer liaison, specification, design, engineering, testing, manufacturing, assembly and shipping in one organization enables us to maintain continuous tracking and quality assessment of your project through every stage.

Taiwa has the capabilities to manufacture single, bespoke electrical equipment enclosures and cabinets for specialized applications as well as the capacity for large production runs. For production runs we can also make model variants on our parallel laser punch cutting and forming lines.

Based in Taiwan, we have the benefit of robust and comprehensive material, service, and logistics supply chains that make it straightforward for us to source the highest quality sheet metals and metal coatings, maintain the highest manufacturing standards and deliver finished products to our customers on time and to exact specifications.

Whether you’re in need of prototype sheet metal parts or high-volume metal fabrication, TAIWA is your trusted sheet metal fabrication provider. Our services encompass:

We help you every step of the way from your initial drawing through to the finished assembled product. Our end to end DFM (Design for Manufacturing) service for custom sheet metal fabrication makes it easy for you to achieve the results you need.

We have a full range of the very latest Japanese laser cutting systems and software for both Fiber and CO2 cutting. We use Amada laser cutting machines capable of handling a wide range of materials including round and square pipe for structural components as well as large sheets.

For projects such as electrical enclosures that require both cutting and punching we have combination Amada systems that complete the cutting and punching in a single set up. This is vital for precision and helps us to control production costs so that you get the best deal.

We use Amada’s cutting-edge simulation software and their HDS and HG series press brakes to deliver unparalleled precision and maintain the aesthetics of our products. Our engineers also undergo over 300 hours of specialized training and obtain Amada certification before managing any client projects.

At Taiwa we use advanced Hitachi welding systems and have expertise in both Argon and CO2 welding of sheet metal and pipe for product components. Each weld is thoroughly inspected and finished to maintain surface quality and aesthetic appeal of each part.

We check and finish every single part to your specifications prior to our assembly team putting it all together, inspecting and finally packaging the products ready to ship to you. Meticulous attention to every detail from the first cut to the final assembly.

Our main fields are sheet metal parts manufacturing for industrial machinery, the optoelectronics industry, electrical control boxes, and metal closures for machinery

Choosing TAIWA means opting for a sheet metal fabricator that stands by its word to deliver excellence. Our metal fabrication and sheet metal enclosure manufacturing are the core of our extensive service offerings. Connect with us today and experience TAIWA’s expert sheet metal fabricator services.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |