Our sheet metal enclosures are engineered to safeguard your critical equipment across diverse industries, including medical, aerospace, food processing, server installations and semiconductor manufacturing.

Crafted from premium materials including SPCC, SUS, SECC, Aluminum, SGCC, and Copper, Taiwa sheet metal enclosures can be customized for durability and reliability in the harshest environments.

With sheet thickness ranging from 0.5mm to 5mm, every enclosure is designed to match your specific needs for optimal protection and structural strength to match your engineering requirement.

From robust covers for machine components to dust-free cases for delicate LCD screen panels, our sheet metal fabrication expertise ensures your equipment is protected and secure without costly over-engineering.

Functionality and aesthetics depend on look and feel as much as ergonomic design.

We can build industrial machinery sheet metal enclosures with a wide range of cosmetic and functional finishes to suit the style you want as well as the durability and utility that you need.

Sheet metal enclosures and cabinets for industrial machinery, including CNC machine cabinets, have many requirements that are easy to achieve by sheet metal fabrication. The following features are common considerations when designing sheet metal shells for industrial cabinets and CNC machine enclosures.

Industrial mechanical equipment requires sturdy structural components to support and protect internal machine parts.

Strength and stability can be provided by sheet metal fabrication of machinery frames, bases, racks and other types of structural support.

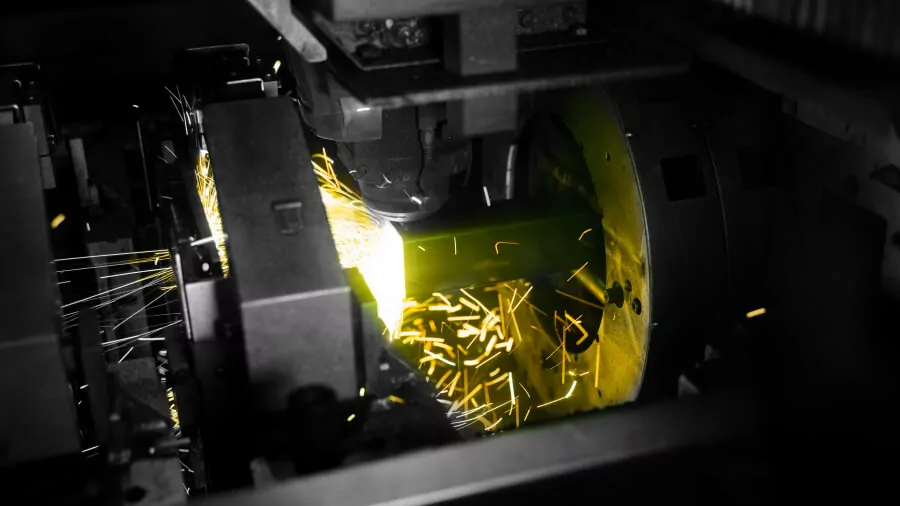

Sheet metal is used to create the outer casings and physical appearance of mechanical equipment to protect the internal mechanisms and components from damage or contamination.

These casings can provide protection, soundproofing, and an aesthetically pleasing appearance.

Sheet metal forming is used to make partitions between different functional components of mechanical equipment.

This is especially important to prevent contamination with lubricants, coolant and metal chippings in CNC machine cabinets.

Cooling systems for industrial machinery include cooling vanes and heat sinks that can be fabricated out of sheet metal as an integral part of the design of the sheet metal enclosure..

Vanes and heat sinks are specified in the engineering design to radiate excess heat and keep machinery operating within the optimal temperature range.

These are some common examples of how sheet metal fabrication is used for industrial machinery sheet metal enclosures. Sheet metal fabrication for machinery and CNC cabinets offers many diverse ways to solve common engineering requirements for different types of industrial machinery in diverse working environments.

Whether you’re in need of prototype sheet metal parts or high-volume metal fabrication, TAIWA is your trusted sheet metal fabrication provider. Our services encompass:

We help you every step of the way from your initial drawing through to the finished assembled product. Our end to end DFM (Design for Manufacturing) service for custom sheet metal fabrication makes it easy for you to achieve the results you need.

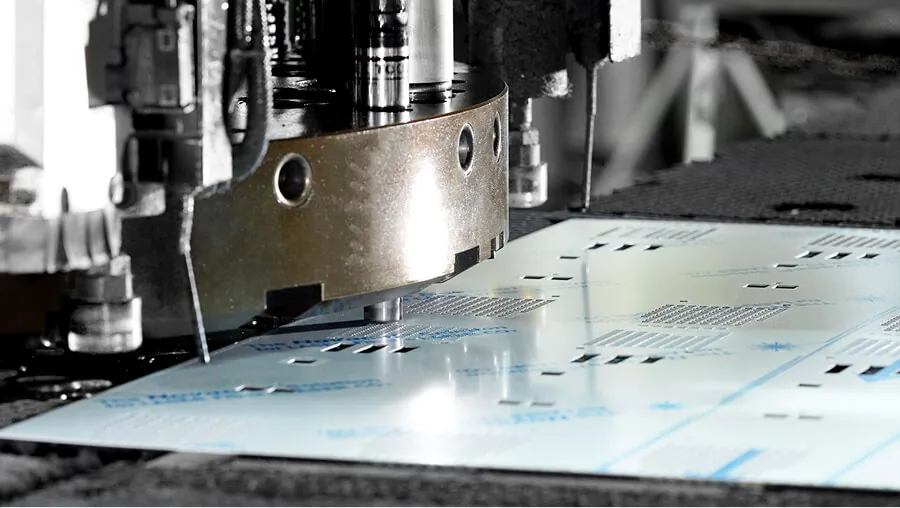

We have a full range of the very latest Japanese laser cutting systems and software for both Fiber and CO2 cutting. We use Amada laser cutting machines capable of handling a wide range of materials including round and square pipe for structural components as well as large sheets.

For projects such as electrical enclosures that require both cutting and punching we have combination Amada systems that complete the cutting and punching in a single set up. This is vital for precision and helps us to control production costs so that you get the best deal.

We use Amada’s cutting-edge simulation software and their HDS and HG series press brakes to deliver unparalleled precision and maintain the aesthetics of our products. Our engineers also undergo over 300 hours of specialized training and obtain Amada certification before managing any client projects.

At Taiwa we use advanced Hitachi welding systems and have expertise in both Argon and CO2 welding of sheet metal and pipe for product components. Each weld is thoroughly inspected and finished to maintain surface quality and aesthetic appeal of each part.

We check and finish every single part to your specifications prior to our assembly team putting it all together, inspecting and finally packaging the products ready to ship to you. Meticulous attention to every detail from the first cut to the final assembly.

Our main fields are sheet metal parts manufacturing for industrial machinery, the optoelectronics industry, electrical control boxes, and metal closures for machinery

Choosing TAIWA means opting for a sheet metal fabricator that stands by its word to deliver excellence. Our metal fabrication and sheet metal enclosure manufacturing are the core of our extensive service offerings. Connect with us today and experience TAIWA’s expert sheet metal fabricator services.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |