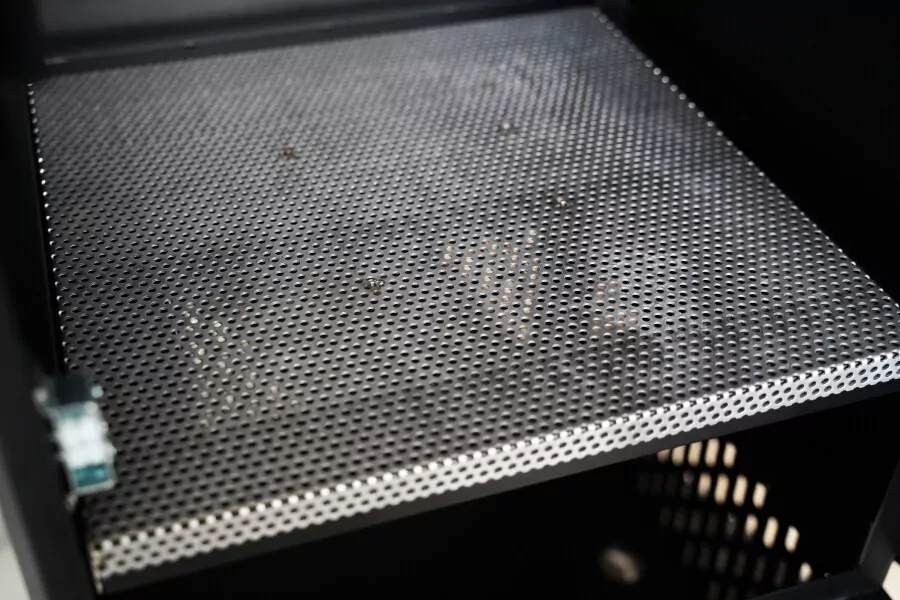

Server cabinets and network cabinets protect and preserve expensive, essential electronic hardware in the modern digital age. Powerful server rack cabinet hardware is sensitive to environmental changes and needs to be isolated from potential contaminants as well as insulated with the correct heat exchange and cooling systems to maintain processors at ideal working temperatures.

Taiwa custom sheet metal fabrication offers the precision and functionality required to make high quality networking and server cabinets of any size and configuration.

Our state of the art AMADA cutting and forming technology and precision welding and assembly enables us to manufacture any design of network or server cabinets no matter how complex the desired configuration.

Network and server cabinets need to provide several key functions to ensure safe and reliable operation of networking and server systems.

The functional design of server rack cabinets includes appropriate racking and attachments to mount standard server processor and memory boards and ancillary components, including power supplies, fans, heatsinks and liquid cooling systems.

The design of network and server cabinets must ensure that temperature levels can be easily maintained even under the highest load conditions, and at the same time protect sensitive electronics from moisture, and environmental contamination.

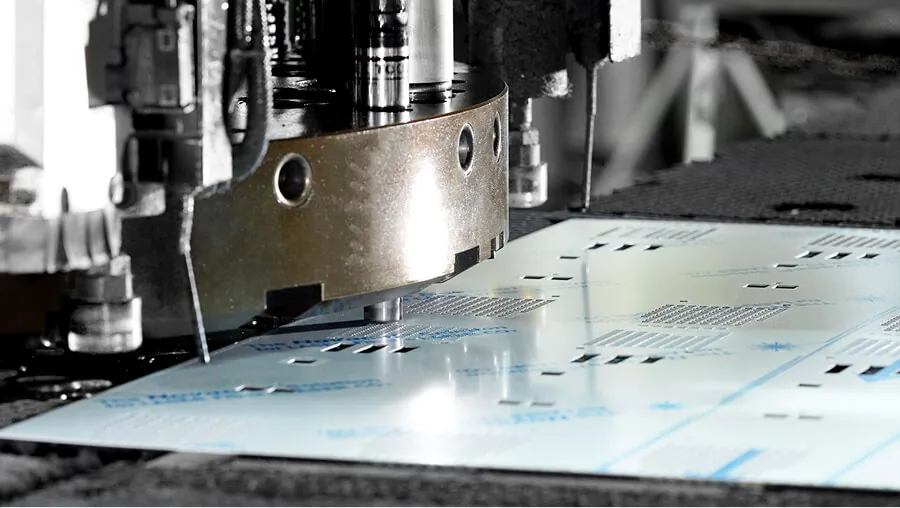

Our sophisticated punch / laser cutter machines are made by leading Japanese manufacturers AMADA, and are a perfect choice for precision custom sheet metal fabrication of network and server cabinets.

The combination of punching and laser cutting in a single pass increases precision and productivity, leading to higher quality results and saving the cost of multiple punching and cutting processes.

Network and server cabinets commonly require both internal racking and specific fixing hardware that will ensure a precise fit for electronic hardware components, as well as guides and retainers for power and data cabling and cooling systems.

Taiwa has extensive experience in custom sheet metal fabrication of complex structures with integrated slots, trays and shelves as well as integrated fixings, hardware fasteners, riveted, stamped, and threaded attachment points.

Taiwa has total control of all stages of sheet metal fabrication from start to finish, with our design studio, machinery and assembly team all working on-site in our state of the art factory in Taiwan.

This makes it easy for us to monitor and maintain quality standards, identify and resolve issues, and give frequent feedback to our customers on the progress and timeline of projects.

When you work with Taiwa, you get the benefit of our experienced design team and qualified engineers. We are happy to advise you on any design and manufacturing features that can be used to refine and optimize your network cabinet design.

Usually we can find ways to make a cabinet design more cost effective without compromising on function and quality.

Taiwa have the precision sheet metal fabrication capability at scale to manufacture any type of server cabinet to meet the needs of IT professionals. We can provide for any rack size from wall-mounted cabinets to floor-standing server rack cabinets with a comprehensive range of customization options.

When choosing a networking and server cabinet manufacturer, flexibility, quality and durability should be at the top of your list of preferences. Taiwa precision sheet metal fabrication builds durable cabinets with the features you need to protect and optimize valuable electronic hardware.

Professional assembly has a significant impact on the stability and durability of networking cabinets and server enclosures, and is advisable to maintain consistent results and reduce the likelihood of faults introduced by a lack of care if components are assembled off-site by third parties.

For networking and server cabinets, we offer a choice of welded assembly or a choice of fasteners and fastening methods both for assembly and for fitting of racks, components, and accessories.

This reflects our experience in designing and manufacturing distortion free cabinets and sheet metal structures where sometimes screws and bolts can be better than welded construction to reduce potential distortion of thin sheet materials and reduce manufacturing costs.

All Taiwa sheet metal fabrication products are assembled on-site by our in-house team. This guarantees excellent quality control from start to finish of the project. From design consultation to finished product, the work in progress never leaves our production facility and our quality managers supervise the entire process.

Cabinets for 5G network hardware, server cabinets and networking cabinets all require attention to task specific environmental, access, and cabling requirements and our design engineers and quality team work together to monitor and ensure these requirements are all met during the design and manufacturing processes.

Taiwa has the technology and capacity to manufacture single, bespoke server cabinets for specialized applications or large production runs. We can also include design variations in production runs with our multiple laser punch cutting and forming lines.

It is also possible to build modular server rack cabinets which can be upgraded to any size and configuration required without compromising on quality and performance.

Whether you’re in need of prototype sheet metal parts or high-volume metal fabrication, TAIWA is your trusted sheet metal fabrication provider. Our services encompass:

We help you every step of the way from your initial drawing through to the finished assembled product. Our end to end DFM (Design for Manufacturing) service for custom sheet metal fabrication makes it easy for you to achieve the results you need.

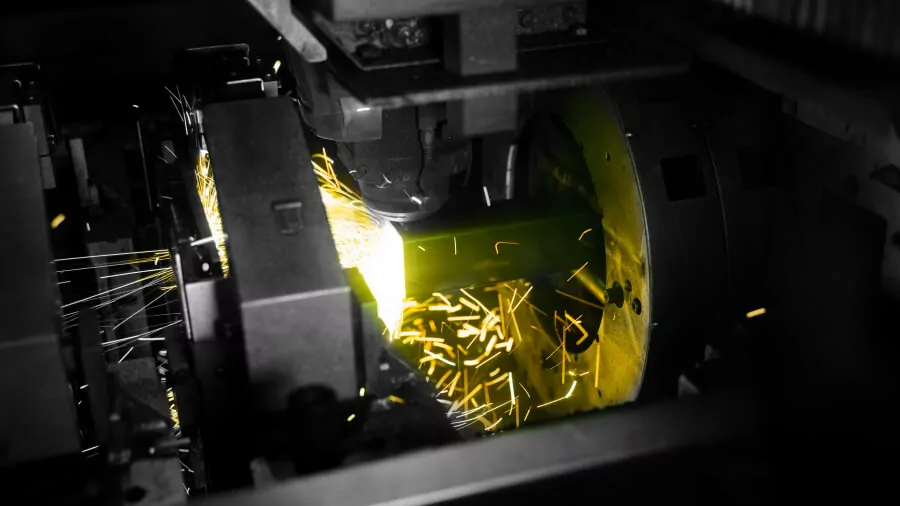

We have a full range of the very latest Japanese laser cutting systems and software for both Fiber and CO2 cutting. We use Amada laser cutting machines capable of handling a wide range of materials including round and square pipe for structural components as well as large sheets.

For projects such as electrical enclosures that require both cutting and punching we have combination Amada systems that complete the cutting and punching in a single set up. This is vital for precision and helps us to control production costs so that you get the best deal.

We use Amada’s cutting-edge simulation software and their HDS and HG series press brakes to deliver unparalleled precision and maintain the aesthetics of our products. Our engineers also undergo over 300 hours of specialized training and obtain Amada certification before managing any client projects.

At Taiwa we use advanced Hitachi welding systems and have expertise in both Argon and CO2 welding of sheet metal and pipe for product components. Each weld is thoroughly inspected and finished to maintain surface quality and aesthetic appeal of each part.

We check and finish every single part to your specifications prior to our assembly team putting it all together, inspecting and finally packaging the products ready to ship to you. Meticulous attention to every detail from the first cut to the final assembly.

Our main fields are sheet metal parts manufacturing for industrial machinery, the optoelectronics industry, electrical control boxes, and metal closures for machinery

Choosing TAIWA means opting for a sheet metal fabricator that stands by its word to deliver excellence. Our metal fabrication and sheet metal enclosure manufacturing are the core of our extensive service offerings. Connect with us today and experience TAIWA’s expert sheet metal fabricator services.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |