Designed and manufactured in Taiwan, our sheet metal enclosures are tailored to meet diverse industry needs including aerospace, semiconductor manufacturing, food processing, and medical applications. Sheet metal enclosures protect machinery from environmental and mechanical hazards, improve worker safety and are essential for industries requiring clean or hygienic working environments. Functional sheet metal enclosures include apertures, removable panels and ports that make it easy to maintain equipment without increasing maintenance downtime.

Sheet metal enclosures can be manufactured at any scale, from small boxes to protect switches through to large free-standing enclosures for heavy machinery. Additional considerations during design include the level of environmental protection required, strength and portability, and cleaning and maintenance needs, especially for clean room and medical sheet metal enclosures.

When you ask Taiwa to help you to manufacture sheet metal enclosures, you get the benefits of our vertically integrated design and fabrication capabilities and technologies. We maintain oversight and quality management of every stage from material sourcing in the supply chain through to finishing, assembly and shipping. This ensures a consistent, responsive approach which keeps you informed and up to date on progress every step of the way as well as ensuring nothing is left out from the original design.

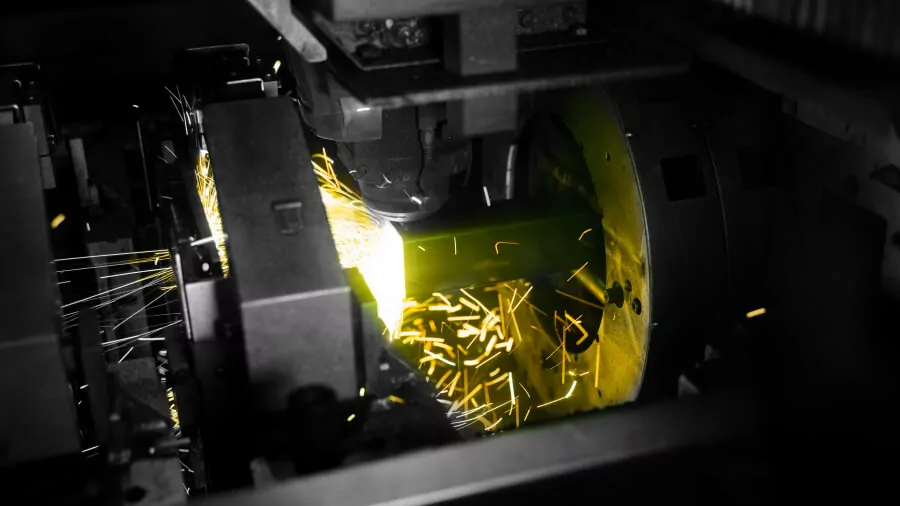

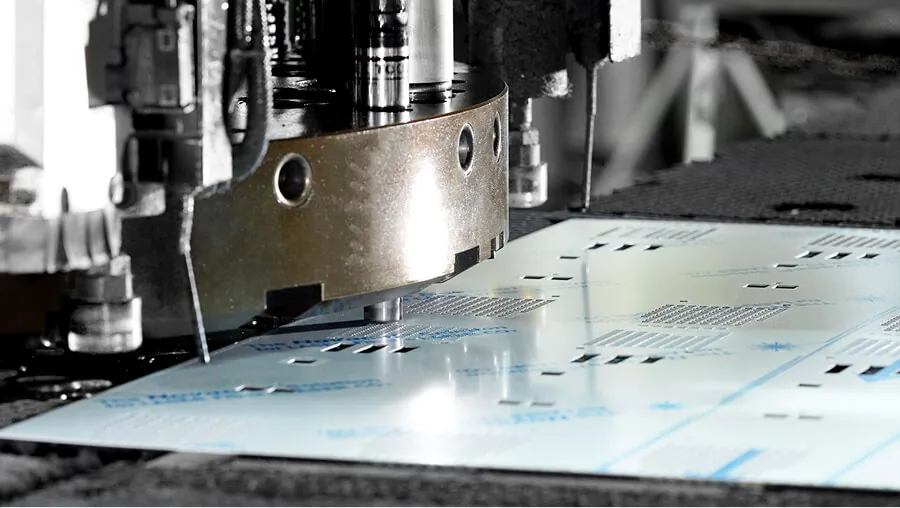

Our state of the art AMADA Japanese CNC laser punch cutting and bending machines combined with our extensive tooling library enable us to ensure that your design is reproduced to very fine tolerances, ensuring a perfect fit with smooth finishing and no last minute modifications no matter how complex your requirements.

Environmental protection of delicate equipment, or machinery operating in hostile environments is an important feature of good sheet metal enclosure design.

We can build sheet metal enclosures to achieve any Ingress Protection (IP) rating, to the IEC 60529 standards, from basic grit and splash proofing to fully sealed units and also include heat sinks, vents of thermal insulation for temperature control.

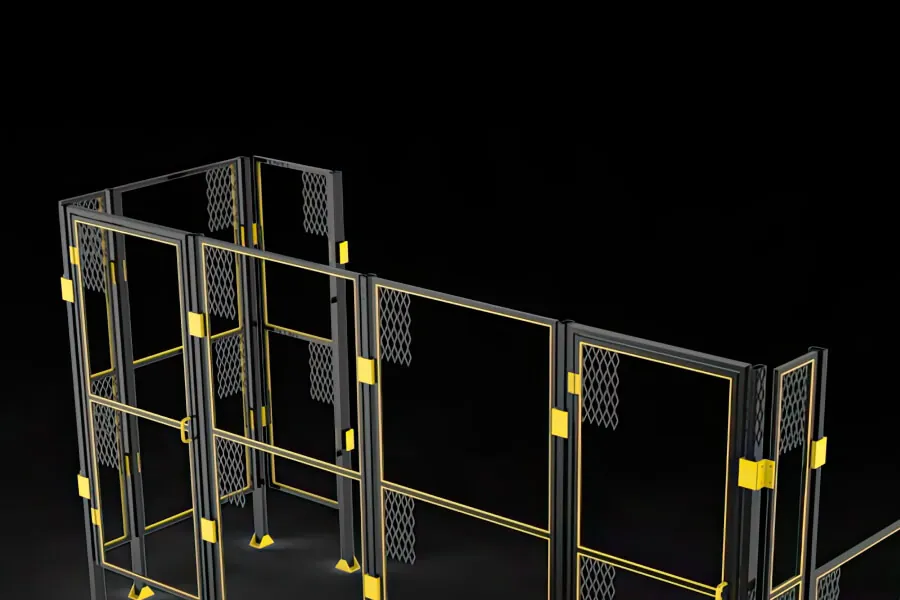

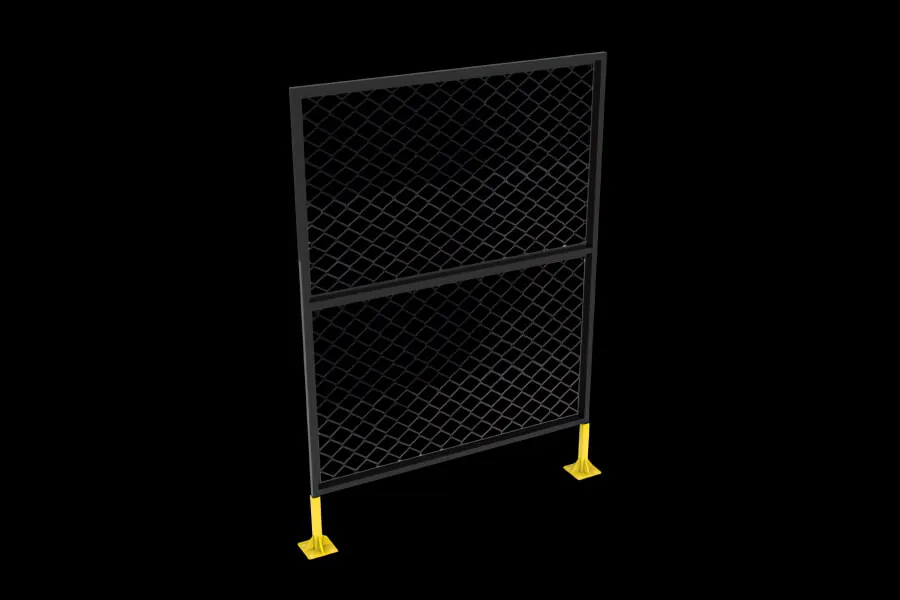

Ensuring workplace safety is a top priority in modern manufacturing environments.

Sheet metal enclosures for machines, electrical equipment, chemical, medical and biological processes provide a reliable barrier to protect workers from hazards, comply with safety regulations and maintain operational efficiency.

Whether you require a lightweight yet durable barrier for sensitive components or a heavy-duty industrial safety fence to enclose high-speed machinery, we can fabricate a solution that meets your specifications.

From clean room enclosures for dust-free semiconductor manufacturing to easily cleaned and sterilized medical and food enclosures, Taiwa can design and build a solution for you.

Experience the cost and installation efficiencies of working with the most precise sheet metal fabrication technology available. Our advanced Taiwanese sheet metal enclosure fabrication technology includes state of the art laser punch cutting and CNC predictive bending and forming to ensure a perfect fit and minimum waste.

We also have an extensive tooling library that can significantly reduce setup costs.

SPCC (JIS G 3141) is a cold rolled hot steel sheet, which is processed for strength and uniformity. The cold rolling process improves the surface of the steel to achieve a smooth, or polished finish. This steel is typically also a low carbon steel, which makes it easier to draw and achieve an excellent finish in thin sheets that are ideal for home appliances and electrical boxes.

SECC is SPCC cold rolled steel which has been electro-galvanized with zinc to reach an average thickness of electrolytic zinc plating of between 2 and 25 µm. Used for machine covers, machine parts, lighting equipment, building materials, and transportation components.

SGCC is hot-dip galvanized cold rolled steel sheet. This achieves a significantly thicker plating of zinc than the electrolytic process used for SECC, and results in an average plating thickness of 50-100 µm. High rust prevention makes SGCC useful for external machinery like air conditioners, ventilation equipment, and vending machines.

Aluminum and aluminum alloys come in a range of grades that have excellent corrosion resistance and are very light in weight compared to steel. This makes aluminum a popular choice for sheet metal aerospace components. High heat conductivity also leads to aluminum being popular for kitchen & cooking utensils.

Copper is highly conductive, can be polished to a bright finish, is highly malleable and easily worked into complex shapes. This makes it ideal for decorative and artisanal sheet metal fabrication, and it can be used for decoration on more functional products to improve visual aesthetics.

Whether you need small or large volume sheet metal enclosures we have the full range of onsite capabilities at our Taiwan fabrication facility to build the perfect product for your project.

We help you every step of the way from your initial drawing through to the finished assembled product. Our end to end DFM (Design for Manufacturing) service for custom sheet metal fabrication makes it easy for you to achieve the results you need.

We have a full range of the very latest Japanese laser cutting systems and software for both Fiber and CO2 cutting. We use Amada laser cutting machines capable of handling a wide range of materials including round and square pipe for structural components as well as large sheets.

For projects such as electrical enclosures that require both cutting and punching we have combination Amada systems that complete the cutting and punching in a single set up. This is vital for precision and helps us to control production costs so that you get the best deal.

We use Amada’s cutting-edge simulation software and their HDS and HG series press brakes to deliver unparalleled precision and maintain the aesthetics of our products. Our engineers also undergo over 300 hours of specialized training and obtain Amada certification before managing any client projects.

At Taiwa we use advanced Hitachi welding systems and have expertise in both Argon and CO2 welding of sheet metal and pipe for product components. Each weld is thoroughly inspected and finished to maintain surface quality and aesthetic appeal of each part.

We check and finish every single part to your specifications prior to our assembly team putting it all together, inspecting and finally packaging the products ready to ship to you. Meticulous attention to every detail from the first cut to the final assembly.

Our main fields are sheet metal parts manufacturing for industrial machinery, the optoelectronics industry, electrical control boxes, and metal closures for machinery

Choosing TAIWA means opting for a sheet metal fabricator that stands by its word to deliver excellence. Our metal fabrication and sheet metal enclosure manufacturing are the core of our extensive service offerings. Connect with us today and experience TAIWA’s expert sheet metal fabricator services.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |