We manufacture steel frame platforms, steel gantries and steel stairs that are engineered for strength, durability and to deliver the special requirements of any industry.

From machinery access stairs to working platforms in a choice of materials including SPCC, SUS, SECC, Aluminum, or SGCC. Taiwa will manufacture sheet metal steel frame platforms, gantries and stairs to your exact requirements.

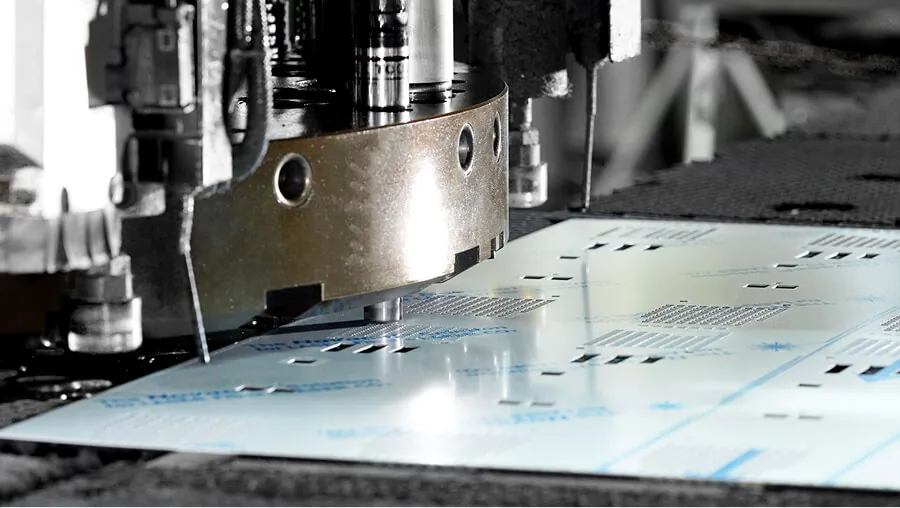

Our modern AMADA sheet metal cutting and bending lines will effortlessly cut and form steel platforms, steel stairs and gantries in sheet metal thickness from 0.5mm to 5mm.

Our experienced engineers optimize sheet metal thickness and design features for structural strength without over-engineering. This ensures the most cost-effective outcome for your steel frame platform project.

Steel stairs, steel gantries and steel platforms can increase health and safety risks if not designed to integrate effectively and safely with your workplace and machinery.

At the consultation stage, our design engineers work with you to ensure that all potential safety features are included in the design and match your needs for a functional, safe, secure and efficient working environment.

Taiwa has the expertise, machinery and experience to manufacture specialist sheet metal surfaces with steel frame supporting structures for any specialist application including food grade and clean room surfaces as well as optoelectronic quality control platforms.

Industrial stairs for your workshop or warehouse are usually combined with rest platforms to meet safety regulations, especially when they are used as a mandatory division between multiple fixed ladders. Platforms are also used to enable branching of industrial staircases and steel gantries to efficiently reach all sides of large static machines.

Taiwa’s expert design engineers will advise you on sheet metal material and design elements that are appropriate for your project based on your specific facility needs, budget, and durability requirements and check to be sure that all stair, platform, gantry and work table components match with each other as well as meeting relevant OSHA / health & safety regulations including horizontal and vertical dimensions of risers and safety rails.

These are some common examples of how sheet metal fabrication is used for industrial machinery sheet metal enclosures. Sheet metal fabrication for machinery and CNC cabinets offers many diverse ways to solve common engineering requirements for different types of industrial machinery in diverse working environments.

Whether you’re in need of prototype sheet metal parts or high-volume metal fabrication, TAIWA is your trusted sheet metal fabrication provider. Our services encompass:

We help you every step of the way from your initial drawing through to the finished assembled product. Our end to end DFM (Design for Manufacturing) service for custom sheet metal fabrication makes it easy for you to achieve the results you need.

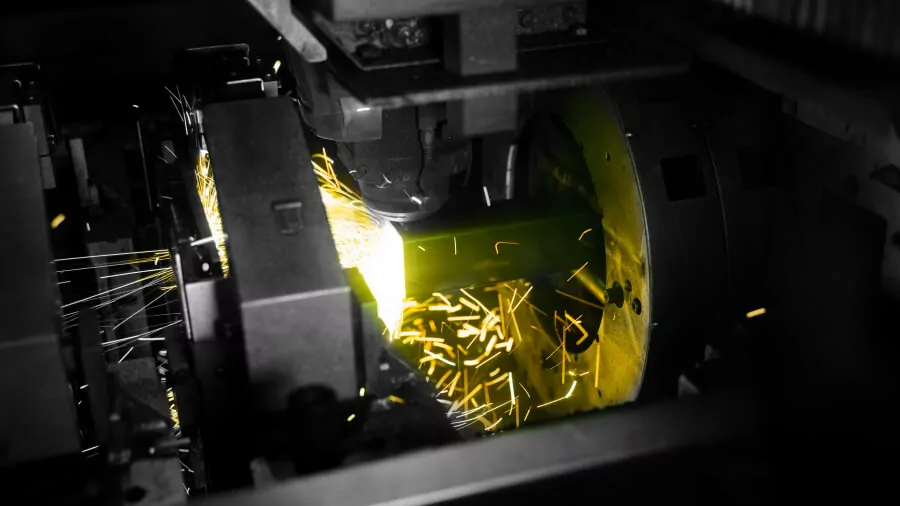

We have a full range of the very latest Japanese laser cutting systems and software for both Fiber and CO2 cutting. We use Amada laser cutting machines capable of handling a wide range of materials including round and square pipe for structural components as well as large sheets.

For projects such as electrical enclosures that require both cutting and punching we have combination Amada systems that complete the cutting and punching in a single set up. This is vital for precision and helps us to control production costs so that you get the best deal.

We use Amada’s cutting-edge simulation software and their HDS and HG series press brakes to deliver unparalleled precision and maintain the aesthetics of our products. Our engineers also undergo over 300 hours of specialized training and obtain Amada certification before managing any client projects.

At Taiwa we use advanced Hitachi welding systems and have expertise in both Argon and CO2 welding of sheet metal and pipe for product components. Each weld is thoroughly inspected and finished to maintain surface quality and aesthetic appeal of each part.

We check and finish every single part to your specifications prior to our assembly team putting it all together, inspecting and finally packaging the products ready to ship to you. Meticulous attention to every detail from the first cut to the final assembly.

Our main fields are sheet metal parts manufacturing for industrial machinery, the optoelectronics industry, electrical control boxes, and metal closures for machinery

Choosing TAIWA means opting for a sheet metal fabricator that stands by its word to deliver excellence. Our metal fabrication and sheet metal enclosure manufacturing are the core of our extensive service offerings. Connect with us today and experience TAIWA’s expert sheet metal fabricator services.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |