Taiwa is a very experienced ODM sheet metal fabrication specialist, and in this case study we’ll look at what goes into making ODM sheet metal outdoor furniture. Every step of the process from material selection to finishing requires attention to detail and quality management to ensure perfect results.

Why is sheet metal the logical choice for outdoor furniture?

Sheet metal fabrication of outdoor furniture is a logical choice as a preferred method for making high quality, durable, public furniture. This includes park benches and picnic tables as well as the types of outdoor furniture people have at home or which are installed at commercial locations. Sheet metal has several advantages over wood, plastics and composite materials for outdoor furniture manufacturing, and this is especially true of manufacturing stainless steel outdoor furniture.

What are common design considerations with sheet metal fabrication?

When you are considering how to make a design by sheet metal fabrication, you need to have a high degree of engineering knowledge and experience to know how to make the most of the high strength of the material while minimizing the weight. Sheet metals are great for fabrication of outdoor furniture and other durable sheet metal products because they have a high strength to weight ratio, but this can result in very heavy designs.

What’s the optimum sheet metal material to use for your outdoor furniture?

You can make sheet metal furniture robust and durable by using heavy gauge materials, but this increases material and manufacturing costs, and may limit the shapes and contours you can make by bending and forming. Sheet metal materials have very widely ranging resistances to corrosion and ways of reacting to weathering effects from sun and rain, so most sheet metals need to have surface coatings to protect them from corrosion and oxidation.

Why is stainless steel the best material for outdoor metal furniture?

- High resistance to corrosion, even in marine environments

- Unaffected by organic decay

- Tough, durable surfaces and structures

- Easily formed into aesthetically pleasing shapes

- High strength to weight ratio allows for portability

- Long life offers cost savings over time

- Can be easily combined with other materials

What will your sheet metal furniture be used for?

You also need to think about the specific outdoor use of your sheet metal furniture. If you are making tables to put in a park it is likely that people will eat at the table and the surfaces need to be resistant to common food acids and oils as well as easy to clean. Some natural wood surfaces are well suited for outdoor use, but synthetic surfaces are usually easier to maintain. Woods with high tannin content can cause acidic corrosion of sheet metals, potentially reducing the lifespan of furniture with wooden seats or cladding.

A case study in outdoor furniture design and sheet metal fabrication

Here we’re going to look at how Taiwa approached the design and manufacturing of a case study in outdoor furniture, creating a harmonious set of stainless steel sheet metal furniture that would demonstrate the desirable features of stainless steel sheet metal fabrication while offering excellent functionality and versatility for public furniture, commercial seating and private outdoor furniture use.

High quality stainless steel sheet metal design & fabrication

At Taiwa we are always working on new sheet metal designs and fabrication techniques, including the manufacture of ODM case studies as well as commercial products for our OEM and ODM sheet metal fabrication customers. Our public furniture designs illustrate our integrated, holistic approach to high quality sheet metal design and fabrication.

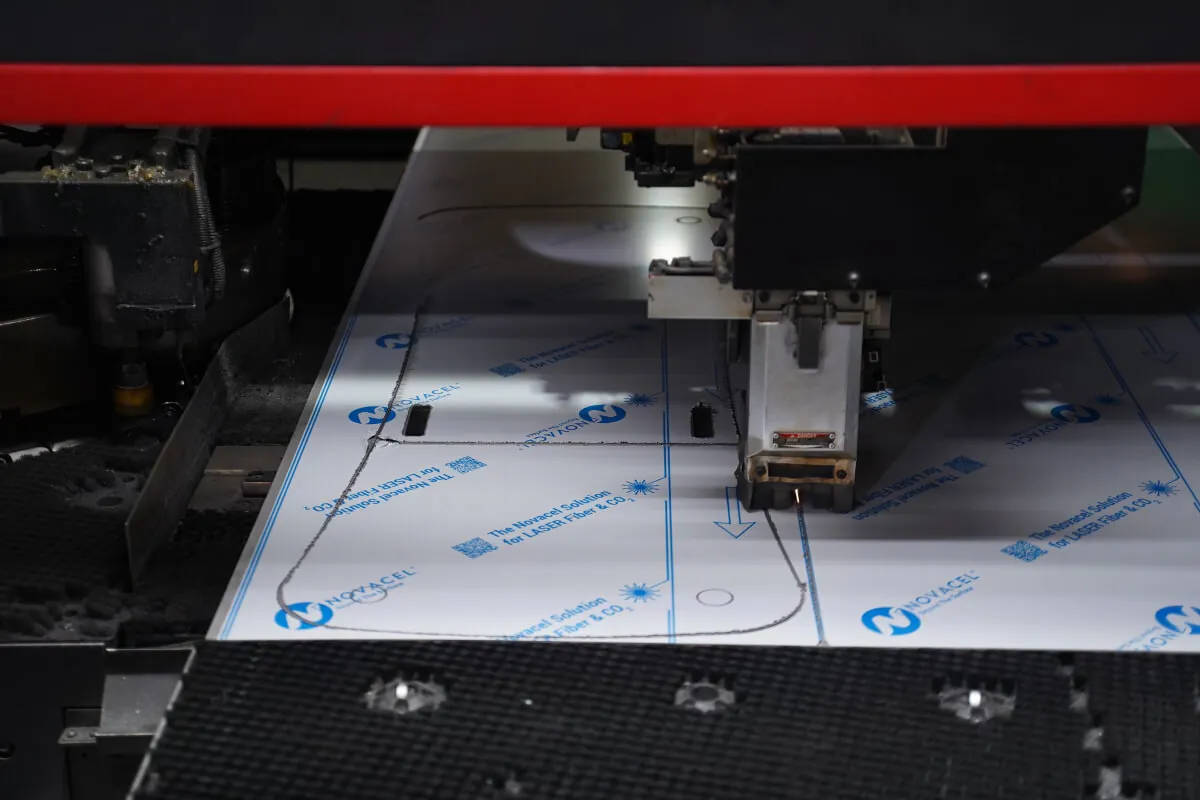

The best technology for accurate sheet metal cutting & bending

Taiwa uses the latest AMADA Japanese laser punch cutting technology as well as AMADA bending machines with CAD predictive forming that anticipates spring back. This is of critical importance in stainless steel bending and forming tasks, as stainless steel exhibits some of the highest levels of resistance to forming of all sheet metal materials.

Inert gas welding for high precision joining of sheet metal components

Inert gas welding is used for joining to ensure the cleanest and smoothest results, including building of bespoke stainless rollers as part of the assembly process for this project. Expert inert gas welding is perfect for attaching stainless steel components with high precision, even when the gauge thicknesses of the steel varies.

Continuous quality control with integrated in-house design & fabrication

During the entire process, our quality control systems are used to check that the results match the engineering design and enable correction if necessary, otherwise you might end up in the final assembly stages of a multi-stage, multi-component job like this and find that the parts do not come together properly. This is where our integrated in-house design, manufacturing and assembly processes are extremely effective in ensuring success.

Taiwa delivers functionality and modular flexibility in outdoor furniture

The resulting design has multiple levels and improves sit / stand functionality for all users of this outdoor furniture. As you can see from the image above, this modular sheet metal design includes a bench seat, a table for people who are sitting down, and a podium height table for the use of people who are standing. The relationship between these three elements is shown in a concept public furniture location by a bus stop in tropical Taiwan. Contact us to find out how we can work with you to build your sheet metal outdoor furniture project.