Manufacturing World osaka 2024 will be held from October 2-4 at INTEX Osaka, featuring 1,200 exhibitors and 35,000 visitors. It is one of Western Japan’s largest trade shows, with 10 specialized exhibitions focusing on digital transformation, factory automation, additive manufacturing, and more.

Taiwa Metal Fab will participate in Manufacturing World Osaka 2024 from October 2-4 at INTEX Osaka. As a leading sheet metal fabricator with over 20 years of experience, we offer custom solutions for various industries, including industrial machinery and electronics.

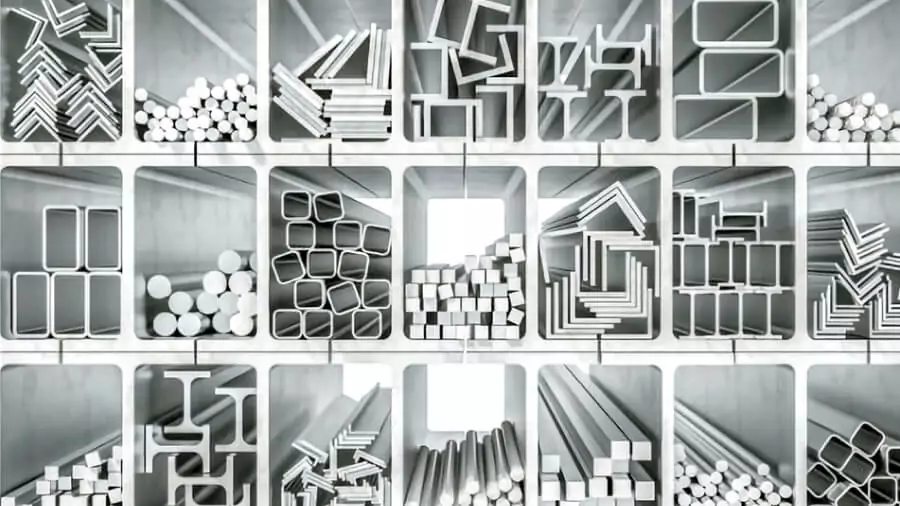

Whether you’re in need of prototype sheet metal parts or high-volume metal fabrication, TAIWA is your trusted sheet metal fabricator. Our services encompass:

We help you every step of the way from your initial drawing through to the finished assembled product. Our end to end DFM (Design for Manufacturing) service for custom sheet metal fabrication makes it easy for you to achieve the results you need.

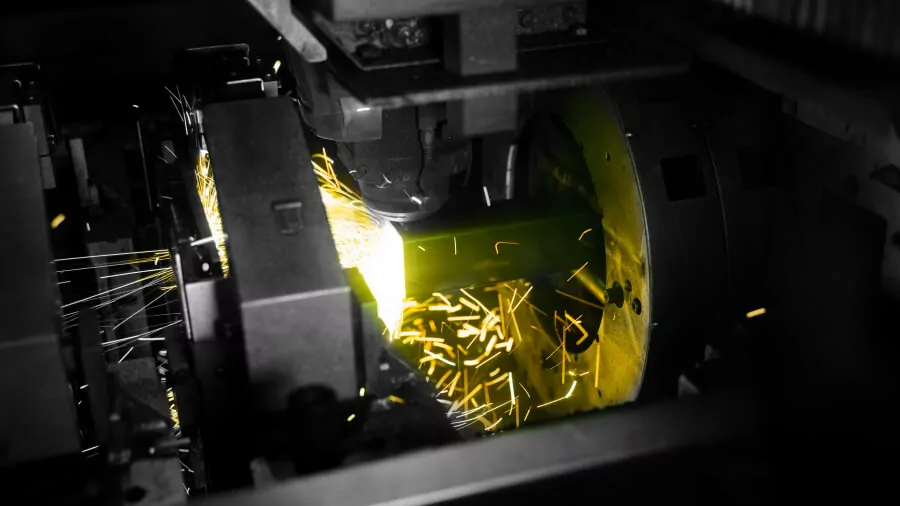

We have a full range of the very latest Japanese laser cutting systems and software for both Fiber and CO2 cutting. We use Amada laser cutting machines capable of handling a wide range of materials including round and square pipe for structural components as well as large sheets.

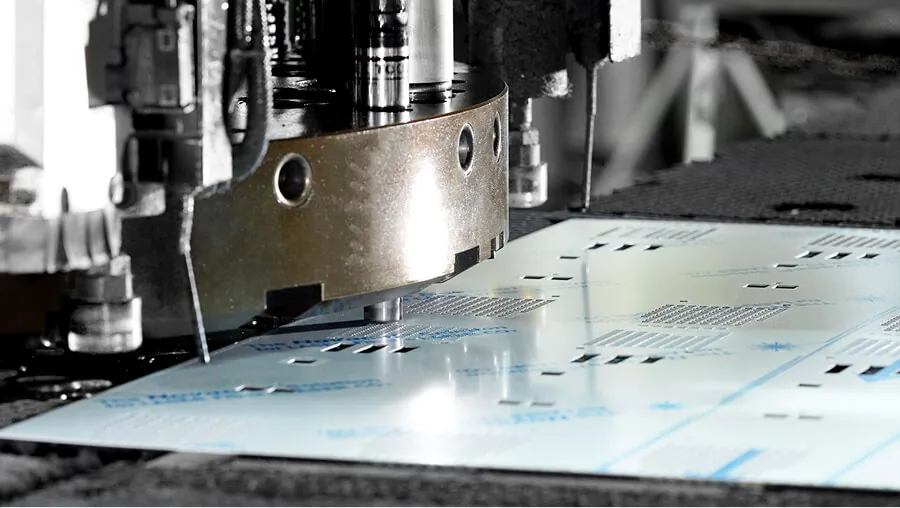

For projects such as electrical enclosures that require both cutting and punching we have combination Amada systems that complete the cutting and punching in a single set up. This is vital for precision and helps us to control production costs so that you get the best deal.

We use Amada’s cutting-edge simulation software and their HDS and HG series press brakes to deliver unparalleled precision and maintain the aesthetics of our products. Our engineers also undergo over 300 hours of specialized training and obtain Amada certification before managing any client projects.

At Taiwa we use advanced Hitachi welding systems and have expertise in both Argon and CO2 welding of sheet metal and pipe for product components. Each weld is thoroughly inspected and finished to maintain surface quality and aesthetic appeal of each part.

We check and finish every single part to your specifications prior to our assembly team putting it all together, inspecting and finally packaging the products ready to ship to you. Meticulous attention to every detail from the first cut to the final assembly.

“Whether you’re in need of prototype sheet metal parts or high-volume metal fabrication, TAIWA is your trusted partner”

At TAIWA, we understand that precision is paramount. As a trusted sheet metal fabricator, we bring your concepts to life with unparalleled precision to meet your project requirements.

Our state-of-the-art facility is equipped with the latest in Japanese CNC sheet metal processing technology, offering everything from laser cutting and punching to metal bending and forming.

Our rapid sheet metal prototyping is a testament to our agility and commitment to meeting tight deadlines without compromising quality. For large-scale projects, our heavy gauge sheet metal fabrication capabilities ensure that every project, regardless of size, receives the meticulous attention it deserves.

We use only the most up to date and advanced Japanese Laser cutting, punching and bending equipment to ensure every part is perfectly produced.

We emphasize the importance of finishing each component and join prior to assembly to guarantee the stable quality of large production runs.

We work with many customers from the design concept phase side by side to ensure the best solutions to meet both your budget requirements and your expectations.

Our main fields are sheet metal parts manufacturing for industrial machinery, the optoelectronics industry, electrical control boxes, and metal closures for machinery

We have collected a range of the frequently asked questions from our customers and listed up some of questions and answers. We hope they assist you when starting new sheet metal fabrication.

If you can not find the answer you are looking for, please feel free to contact us by phone, email or contact form. We would be happy to help you in more detail.

Typically, standard quotations are provided within 5 days, while more complex design drawings may require 7-10 days for a comprehensive response.

We accept and work with design files in AutoCAD and SolidWorks formats. For 2D drawings, DWG and DXF formats are preferred, while for 3D drawings, we recommend STP and IGS formats.

We accept sketches, 2D, and 3D files. However, if providing a sketch, there may be an additional charge for computer-aided drawing services.

The lead time for sample production depends on the complexity of the drawing, the completeness of the provided files, and whether surface treatment is required. Typically, it is within 2 weeks. Feel free to contact us for a quotation.

Our company ensures confidentiality through the signing of a Non-Disclosure Agreement (NDA) between both parties. Quotations and communication are conducted through secure email channels. We employ a rigorous electronic drawing system to control and safeguard customer confidential information.

We have a team of 9 mechanical engineers in the design department and 2 product designers.

Find out our latest exhibition and news.

Choosing TAIWA means opting for a sheet metal fabricator that stands by its word to deliver excellence. Our metal fabrication and sheet metal enclosure manufacturing are the core of our extensive service offerings. Connect with us today and experience TAIWA’s expert sheet metal fabricator services.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |