We combine the most advanced Japanese sheet metal bending systems with extensive staff training to provide you with the most efficient and high precision bending solutions for your products

TAIWA stands out as a provider of choice for businesses looking for reliability and quality. With our advanced Japanese equipment and expertise, we ensure that every bend meets your exact specifications.

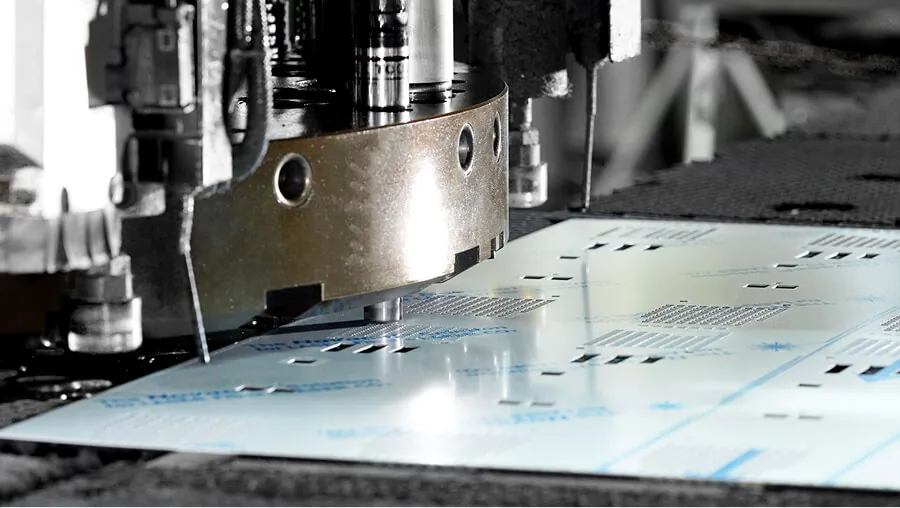

We operate state-of-the-art Japanese AMADA bending machines that offer unparalleled accuracy and efficiency. We pre-simulate bending sequences using Amada SheetMetal software which allows us to anticipate and eliminate potential issues before they arise. This ensures a seamless production process. Additionally, TAIWA’s range of machine sizes and our adaptive approach mean that no matter the demand, we deliver high responsiveness and efficiency.

Every bend is shaped by our professional and certified technicians with over 300 hours of training on our AMADA bending machines. All of our sheet metal bending machines are regularly calibrated and maintained to ensure peak performance and accuracy with every bend. We have a range of machine sizes to suite different project requirements.

One of the significant advantages of partnering with TAIWA is our extensive selection of dies, enabling us to handle a wide variety of jobs with multiple material types and thicknesses.

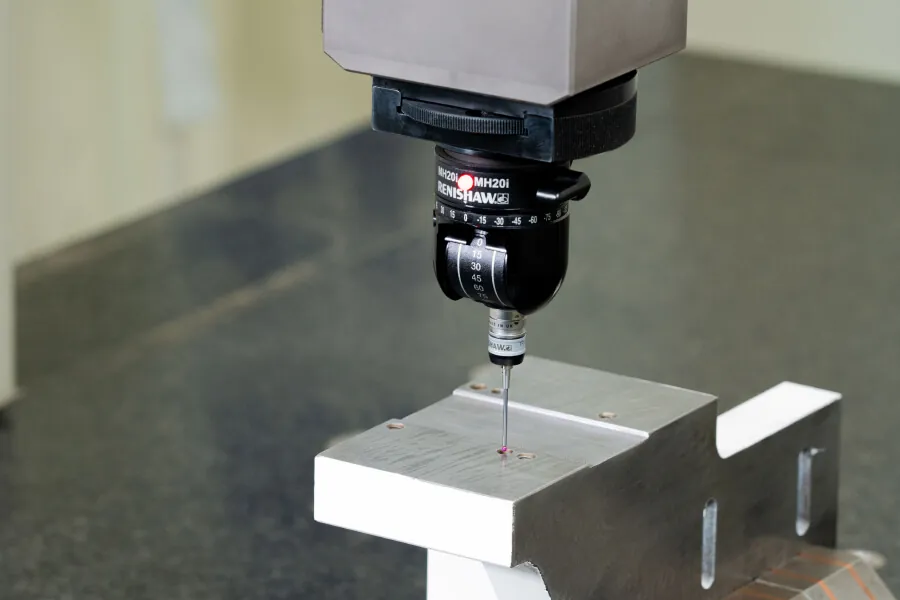

At Taiwa, we prioritize quality management in every aspect of our sheet metal bending services. We check the bending angle of every piece produced, taking measurements on each side to ensure precision and consistency. There are no creases in the materials after bending.

We have dedicated quality control teams that utilize PING inspection methods to maintain the highest quality standards.

We have collected a range of the frequently asked questions from our customers and listed up some of questions and answers. We hope they assist you when starting new sheet metal fabrication.

If you can not find the answer you are looking for, please feel free to contact us by phone, email or contact form. We would be happy to help you in more detail.

Typically, standard quotations are provided within 5 days, while more complex design drawings may require 7-10 days for a comprehensive response.

We accept and work with design files in AutoCAD and SolidWorks formats. For 2D drawings, DWG and DXF formats are preferred, while for 3D drawings, we recommend STP and IGS formats.

We accept sketches, 2D, and 3D files. However, if providing a sketch, there may be an additional charge for computer-aided drawing services.

The lead time for sample production depends on the complexity of the drawing, the completeness of the provided files, and whether surface treatment is required. Typically, it is within 2 weeks. Feel free to contact us for a quotation.

TAIWA uses the Japanese AMADA series for all our bending processes, ensuring top-quality and precision in every job.

We can handle bending projects up to 3000 mm in length, accommodating large-scale industrial needs.

Our equipment is versatile enough to bend metal from as thick as 20mm to as thin as 0.3mm.

After processing, the flatness of our sheet metal is maintained within 0.2mm, and we do have leveling equipment to ensure optimal flatness.

The verticality of our processed metal is within 0.15mm, which showcases our precision bending capabilities.

The minimum flange we can bend varies according to the thickness of the plate. We adjust our techniques to accommodate the specific requirements of each project.

Yes, we can provide the expansion coefficient used during the unfolding process to ensure accurate bending and fabrication.

Our company ensures confidentiality through the signing of a Non-Disclosure Agreement (NDA) between both parties. Quotations and communication are conducted through secure email channels. We employ a rigorous electronic drawing system to control and safeguard customer confidential information.

We have a team of 9 mechanical engineers in the design department and 2 product designers.

Whether you’re in need of prototype sheet metal parts or high-volume metal fabrication, TAIWA is your trusted partner. Our services encompass:

We help you every step of the way from your initial drawing through to the finished assembled product. Our end to end DFM (Design for Manufacturing) service for custom sheet metal fabrication makes it easy for you to achieve the results you need.

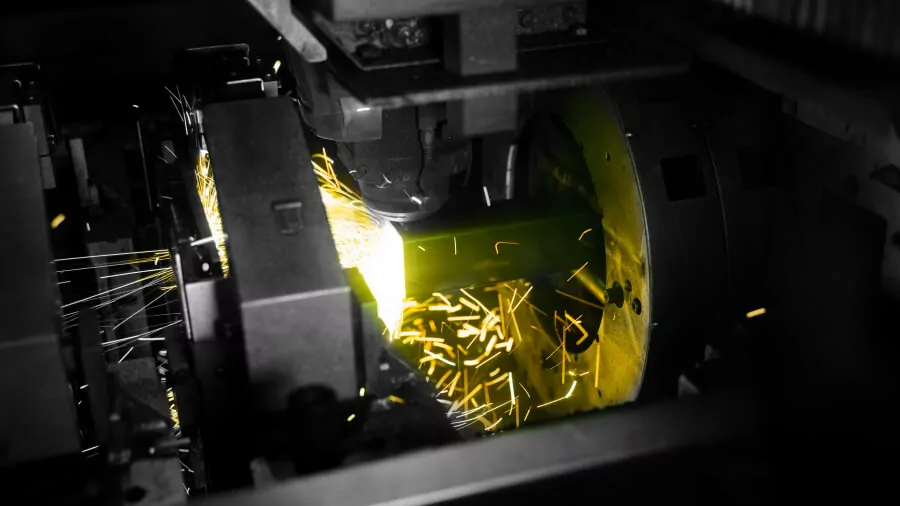

We have a full range of the very latest Japanese laser cutting systems and software for both Fiber and CO2 cutting. We use Amada laser cutting machines capable of handling a wide range of materials including round and square pipe for structural components as well as large sheets.

For projects such as electrical enclosures that require both cutting and punching we have combination Amada systems that complete the cutting and punching in a single set up. This is vital for precision and helps us to control production costs so that you get the best deal.

We use Amada’s cutting-edge simulation software and their HDS and HG series press brakes to deliver unparalleled precision and maintain the aesthetics of our products. Our engineers also undergo over 300 hours of specialized training and obtain Amada certification before managing any client projects.

At Taiwa we use advanced Hitachi welding systems and have expertise in both Argon and CO2 welding of sheet metal and pipe for product components. Each weld is thoroughly inspected and finished to maintain surface quality and aesthetic appeal of each part.

We check and finish every single part to your specifications prior to our assembly team putting it all together, inspecting and finally packaging the products ready to ship to you. Meticulous attention to every detail from the first cut to the final assembly.

Find out our latest exhibition and news.

Choosing TAIWA means opting for a sheet metal fabricator that stands by its word to deliver excellence. Our metal fabrication and sheet metal enclosure manufacturing are the core of our extensive service offerings. Connect with us today and experience TAIWA’s expert sheet metal fabricator services.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |