Choosing an ODM partner with the right balance of expertise, capabilities and capacity can make all the difference to your sheet metal fabrication project. Even the simplest sheet metal designs benefit from working with professional fabricators to develop the best possible version of your idea. From assessing the correct materials through to knowing how to achieve the best finishes, an ODM partner should be with you every step of the way to guarantee success.

What is ODM in sheet metal fabrication?

Original design manufacturing (ODM) in sheet metal fabrication is when an expert sheet metal fabrication business develops an idea or specification for a sheet metal product with you to create a finished, ready for market, product. ODM is different from Original Equipment Manufacturing (OEM) because the ODM fabricator takes a more active role in refining and perfecting the product design. An OEM sheet metal fabricator makes a product from engineering drawings supplied by the customer, but an ODM fabricator is an active partner in the entire process.

Is an ODM sheet metal fabricator better than an OEM sheet metal fabricator?

When you are starting out with any sheet metal fabrication project, you need to be very aware of your own knowledge, capabilities, and limitations. If you have your own expert sheet metal design and fabrication skills and experiences to work from, then you may be able to design a perfect sheet metal product without assistance from the fabricator. This does require you to have a lot of knowledge about how the fabrication process controls design parameters as well as materials, engineering characteristics, and how design features affect ease of use.

Why is a full service sheet metal fabricator better for ODM projects?

Many sheet metal fabrication companies outsource one or more of the processes that are required to complete your project, and this can cause delays and quality issues. It’s better to work with a vertically integrated, full service, sheet metal fabrication company that has close control over the whole process. For the best results, sheet metal cutting, forming, bending, joining, assembly and finishing should be supervised and managed by one team.

ODM sheet metal fabricators offer a fresh perspective

No matter how expert and experienced you are in sheet metal design and fabrication, it’s very helpful to have a fresh perspective, which is why an ODM specialist can add value to even the most carefully planned OEM sheet metal project. It is actually not too difficult to design sheet metal products with simple shapes, like boxes, and most fabricators will simply follow your instructions and make the product exactly how you have drawn it.

Complex sheet metal designs add a new level of challenges that require expert input to achieve the best, most efficient result. Design for Manufacturability (DFM) is an important consideration that expert sheet metal fabricators always apply to improving and refining designs, and it takes experience and technical knowledge to get it right.

Experienced sheet metal fabricators are the best ODM partners

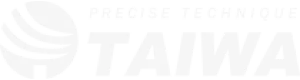

In the example of a simple box design, an ODM expert might be able to save you significant costs by, for example, suggesting a simple folded edge for stiffness that allows you to reduce the thickness of the sheet material by 50% overall without compromising on the structural integrity. The reason why this is possible is usually related to the extensive experience that established sheet metal fabrication companies have, built out of hundreds, or thousands of completed projects. You gain from their experience when you engage in an ODM partnership.

Does having the latest equipment really make a difference to ODM projects?

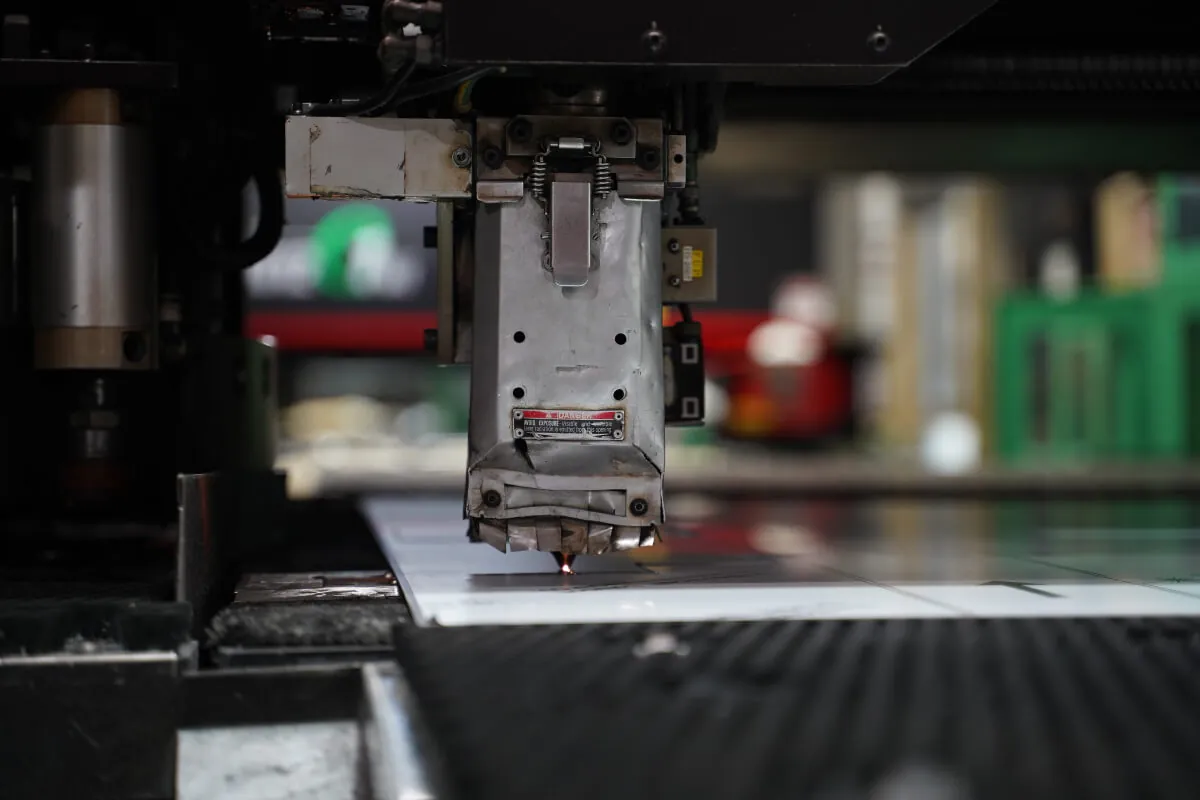

You should check if the sheet metal fabricator has efficient, precision, up to date equipment and systems. There is a world of difference between modern CAD based computer assisted cutting and forming technology and entirely manual machinery, and this is reflected in the quality of results. Modern machines give much better results, more quickly, with less waste.

How should an ODM partner work with you on your sheet metal project?

A good ODM partner for your sheet metal project will work with you throughout all stages of the project, from initial review of your design concept through prototyping, refinement, finalizing designs and manufacturing the finished product. There are many important processes that need to be managed efficiently if your ODM sheet metal fabrication project is to succeed, and be completed to your specified quality, by a defined time, within your cost constraints.

What are the key steps in an ODM sheet metal fabrication project?

- Clarify and explore the initial design concept with the customer

- Assess functionality & features of the product

- Identify possible issues with cost effective manufacturing

- Discuss potential changes, improvements & refinements with the customer

- Finalize the initial design for manufacturing

- Cutting & shaping of all the sheet metal parts

- Incorporating fasteners & fastening components

- Fettling & surface finishing of sheet metal parts

- Welding, fastening & assembly of components to build the finished product

- Adding surface treatments included in the design criteria

- Quality checks, packaging & shipping

The reason these processes, stages, and key steps are important is because they keep the project on track and within scope. What you don’t want is to have a single meeting, sign a contract and then hear nothing for a long period of time, perhaps ending up with your choice of fabricator revealing hidden costs and problems that need to be addressed before continuing. A good ODM partner will keep you informed and build the project together with you with clear, timely aims and objectives that you decide together.

Discover better ODM sheet metal fabrication with Taiwa

Taiwa is a full-service, vertically integrated ODM, OEM and OES sheet metal fabrication company based in Taiwan, with access to high quality raw materials and excellent global supply chains. We offer you decades of experience working on every type of sheet metal fabrication project, from the simplest machinery housings through artistic projects, complex street furniture, and culinary products that effortlessly blend form and function.

We not only have the latest Japanese AMAD CAD technology, we also have a well equipped tooling library, which makes it likely that we can get to work on your project very rapidly without the delay or additional costs of specialist tooling. We take pride in the quality and success of our ODM partnerships. Contact our ODM team, who are always happy to discuss potential new projects regardless of your level of experience or technical expertise.