Taiwa has superior capabilities in original design manufacturing (ODM) partnerships for sheet metal fabrication projects. We combine in-depth technical knowledge with decades of practical experience to assist our ODM clients in realizing the perfect design for manufacturing their sheet metal product. Once the design is finalized, our state of the art sheet metal fabrication technologies and expert staff ensure the results are spectacular.

What are the key stages of ODM sheet metal fabrication with Taiwa?

When we work on an ODM sheet metal fabrication project with a client, like we did with Iroda (pictured above) on this unique table-top fire feature, there are several key stages to the project design and manufacturing process. The first stage is a review of the initial design concept, desired functionality and features of the product with the customer.

At this stage we work with our customer to identify strengths and weaknesses that arise from examining the design based on our extensive knowledge and practical experience of sheet metal fabrication. We then discuss how any necessary adjustments can be worked into the product with minimal impacts on the design concept. At the end of this stage we will have a final version of the design that is optimized for manufacturing.

What 5 elements comprise the first stage design review for sheet metal ODM?

- Clarify and explore the initial design concept with the customer

- Assess functionality & features of the product

- Identify possible issues with cost effective manufacturing

- Discuss potential changes, improvements & refinements with the customer

- Finalize the initial design for manufacturing

A very important focus of ODM is ensuring that even if the product requires changes, perhaps to make a complex design cost-effective to manufacture, the product still stays as close as possible to the original design concept of the customer. Of course it is entirely possible that during the initial review we will find possible adjustments that change the design in a way the customer themselves has not thought of, and which the customer may wish to include in a revised version.

How does a Taiwa sheet metal ODM project become an ODM product?

The next stage is to transform the ODM project into a finished ODM product, this second stage is the manufacturing stage. Depending on the complexity and type of sheet metal project, there may be two phases to this stage, with prototypes being manufactured and incremental design changes being made before moving forward to produce the final product.

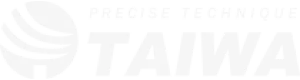

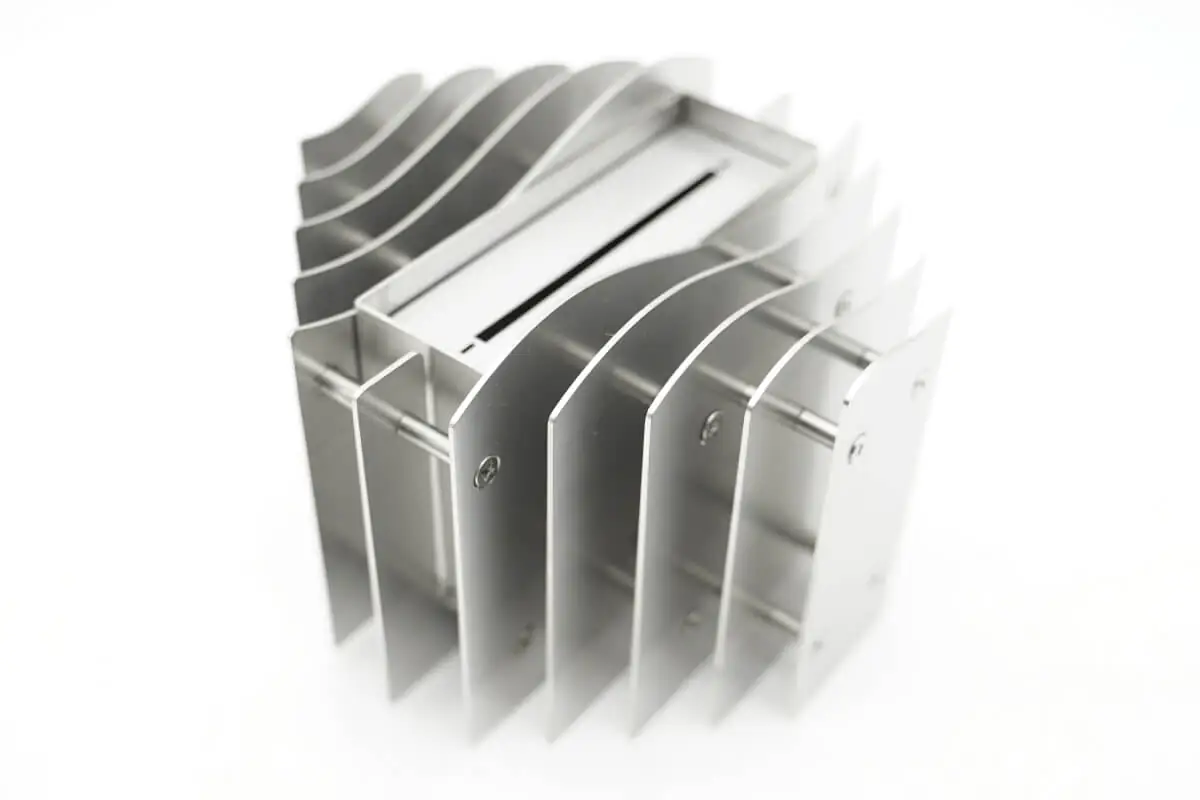

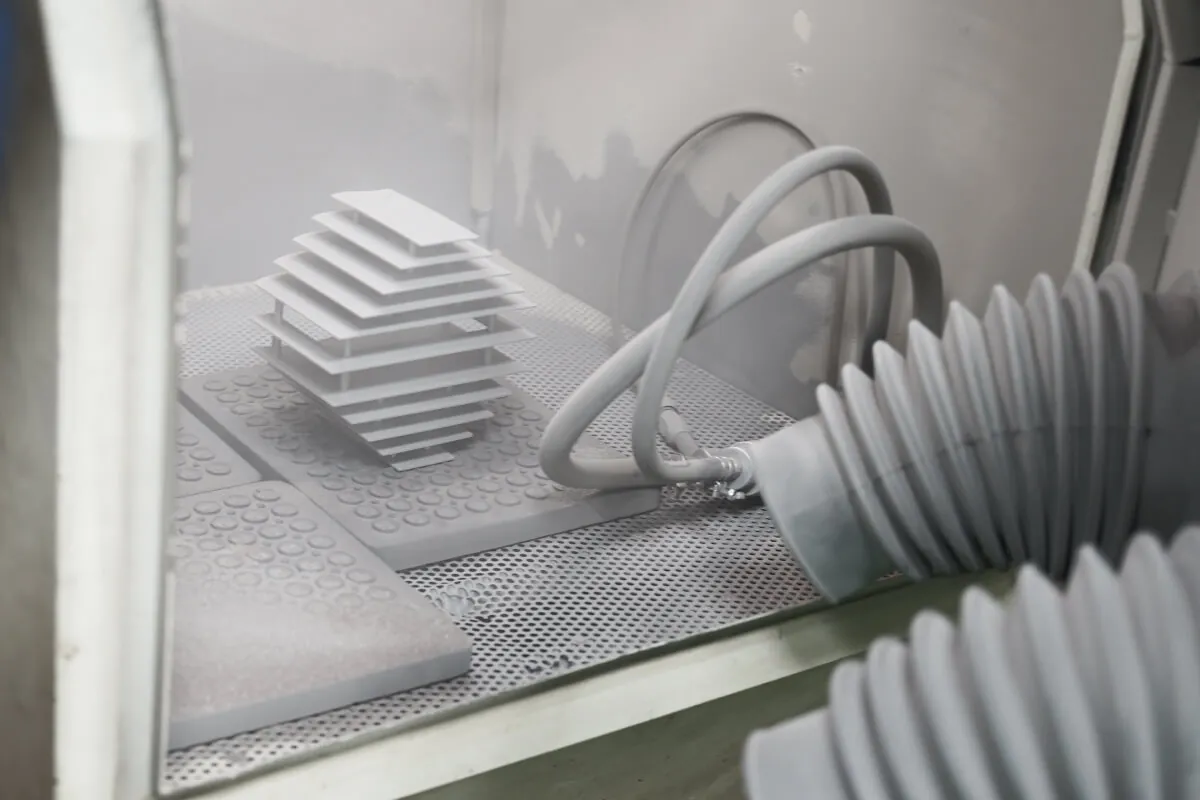

Sometimes during the initial manufacturing stage, prototypes may become alternative versions of the same product, perhaps for aesthetic reasons, as is the case with the tabletop ornamental torch we’re using to illustrate the process. The sequence of images above gives an overview of the laser punch cutting, forming, bending, joining and fastener installation processes with CAD predictive forming and continuous quality control of dimensions to ensure a perfect fit.

What are the 7 elements in the second stage of sheet metal ODM manufacturing?

- CAD controlled laser-punch cutting of all the sheet metal parts

- Forming & bending using precision CAM forming machines & appropriate tooling

- Drilling, countersinking & adding fastening components

- Fettling & surface finishing of sheet metal parts

- Welding, fastening & assembly of components to build the finished product

- Adding surface treatments included in the design criteria

- Quality checks, packaging & shipping

The images above show the assembly and finishing stages after all cutting, bending and fastener mountings have been completed. When the design fundamentals and functionality of a product are unchanged, it is often possible to make design variations that can easily be replicated using CAD technology and CAD laser-punch cutting equipment to cut out sheet metal components. Where the variation is a change in visual style which does not affect functionality this can be reliably replicated at any volume by adjusting the CAD design.

How does Taiwa ensure clarity and quality in ODM manufacturing?

We want every ODM sheet metal fabrication product to be a success as much as our customers do. It is essential to maintain clear communications and have effective continuous quality control and feedback to maintain clarity of purpose and ensure that the results match the vision of the client. Fortunately because we use advanced technology for design and manufacturing processes, it is usually quite straightforward to make minor adjustments in the manufacturing process without having to completely revise the original design work.

What are 3 Taiwa processes that support ODM sheet metal manufacturing?

- Quality checking and verification of processes and outcomes

- Regular feedback and review of progress and status with the customer

- In-process refinements and minor adjustments as required

We have very robust quality control and progress review systems because we operate a vertically integrated sheet metal manufacturing facility, with direct control of every stage from design through production, assembly and packaging. We do not outsource any stages, so it is very easy for us to maintain a clear record of progress and to rapidly identify and communicate both any issues that may arise, and to incorporate any adjustments of process refinements that might be required.

Taiwa partnerships for ODM sheet metal fabrication

This example project involved ODM of a tabletop ornamental fire pit with Iroda, a global leader in flame, torch, lighting and burner technologies. We built an excellent relationship working with the CEO and his engineers, and this is how ODM sheet metal fabrication services should be. The final design and manufacturing successfully captured the Iroda vision for how the product should function as well as delivering a variety of aesthetic versions with the same functionality to appeal to different customer segments.

Why is Taiwa the perfect partner for ODM sheet metal fabrication?

- Comprehensive suite of state-of-the-art sheet metal fabrication machinery on-site

- Extensive tooling library reduces or eliminates tooling costs

- Professional, meticulous product assembly

- Excellent supply chain partnerships

- Very experienced CAD design and development engineers

- Friendly, approachable and responsive project management team

If you have a sheet metal project that you would like to explore with us you don’t need to worry about your technical expertise or understanding of sheet metal fabrication, our ODM engineering team will be happy to guide you through the process from start to finish, and give you the benefit of our in-depth design experience and superior manufacturing capabilities. Contact us to find out more about how we can help you realize your ODM project.